DN Solutions Aerospace

Solutions

Aerospace Solutions

Machine tools are essential for the precise manufacturing and production of aeronautical components,

which have a critical impact on the safety and performance of aircraft.

DN Solutions offers optimal solutions for the precision machining of special metals and composite materials for the production of complex structural components as well as turbine blades and other engine parts.

- 400 R&D staff For Various Materials

DN Solutions has exceptional solutions for difficult-to-machine materials thanks to our diverse experience and R&D capabilities

- 500+ aerospace customers in the world For Various Customers

Most leading companies and

their partners choose DN Solutions - 400 models For Various Applications

DN Solutions has to meet the demands of the aerospace industry.

- The future of aerospace Excellent Technology

DN Solutions provides stable and optimal solutions with excellent technology, ranging from aerospace industry to space industry.

Aerospace Solutions Reference

Older and less efficient airplanes will be replaced with a more efficient, newer generation of airplanes.

During this generational shift, companies can take advantage of opportunities for additional growth.

Body : Aircraft Door Hinges, Aircraft Structural Components, etc.

Component : Various Components, Main Rotor(Helicopter), etc.

Tail : Tail Hangers, Frame, In-Flight tanker Part, etc.

Wing : Rib Support

Case : Engine Case, Turbine Disk, Engine AFT Inner, Engine Forward, Blisk, Engine part, Engine casering, etc.

Blade : Aerofoil (engine Blade), Engine Fan Blades, Geared Turbo Fans

Disk : Brake Disk

-

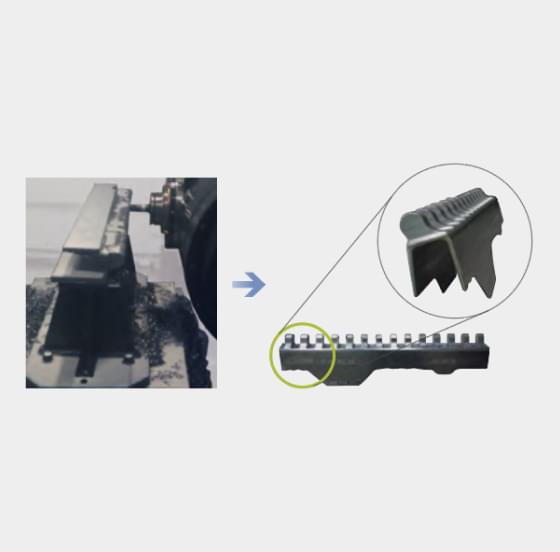

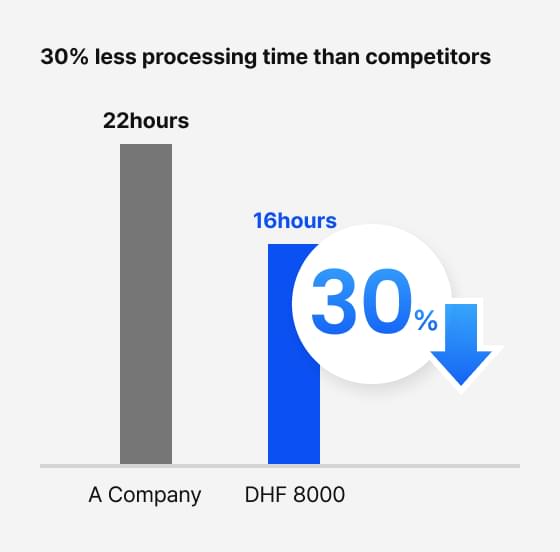

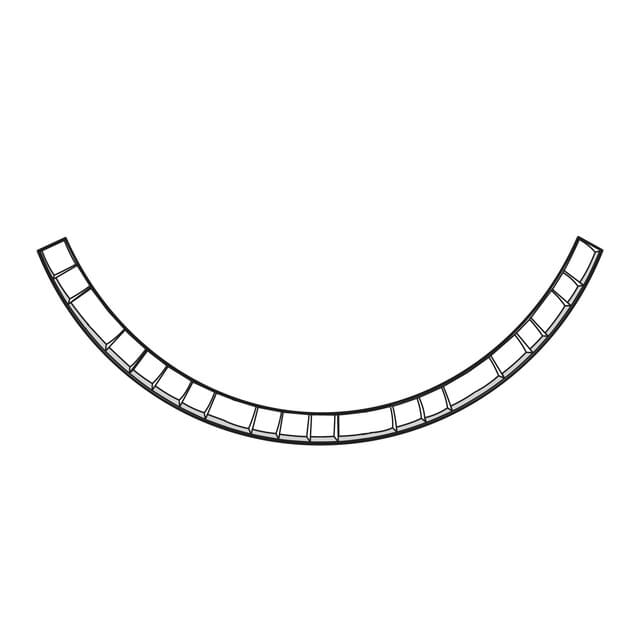

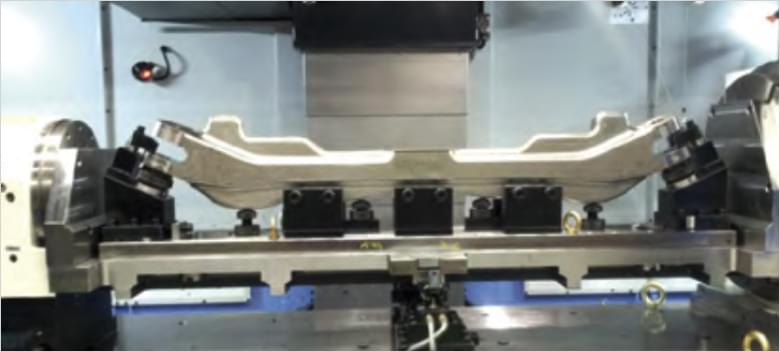

Aircraft Door Hinges Aircraft Door HingesCharacteristics of machining- More economical solution than a company

- Guarantee accuracy

- Curved workpiece

- Material: titaniume

Machining Process

Machining Process Process Tooling Cutting condition Roughing Ø42.0 Insert mill 700mm/min, 400r/min Semi-finishing Ø20.0 R3.0 End mill 600mm/min, 1200/min Finishing Ø20.0 End mill (45˚ 6 flutes) 150mm/min, 250/min Productivity Improvement

When I used a Japanese 5-axis machine to make this part, cutting tools were totally broken because of the low rigidity. Now I use the DHF 8000. This machine has enough power to cut titanium parts with the high precision needed to meet strict conditions of the OEM. There are no precision issues on this machine now. - Plant Manager of Y company

-

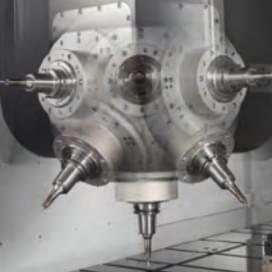

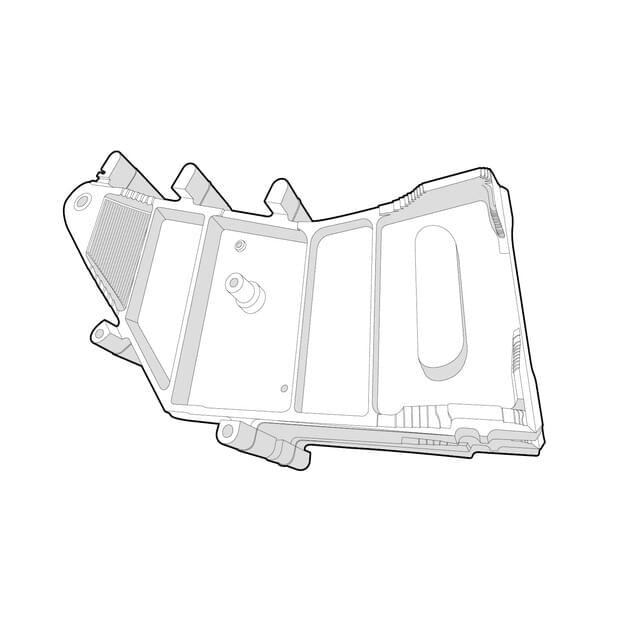

Aircraft Structural Components Aircraft Structural ComponentsCharacteristics of machining- Large size workpieces

- Curved shape

- Simultaneous 5-axis

- Material: aluminum

Various Spindle Line-up

Speed

Speed- 12000~30000 r/min

Power- 30~75 kW

Torque- 143~48 N·m

-

Tail Hangers Tail HangersCharacteristics of machining- Guarantee productivity

- High torque boring

- Compact working area

- Material: aluminum

Various Spindle Line-up Torque

Torque- 1137 / 1273 N·m

Power- 26 kW

Speed- 3000 r/min

Working AreaTravel- X axis 2000 mm

- Y axis 1500 mm

- Z axis 1200 mm

- W axis 500 mm

Table Size- 1400 x 1600 mm

-

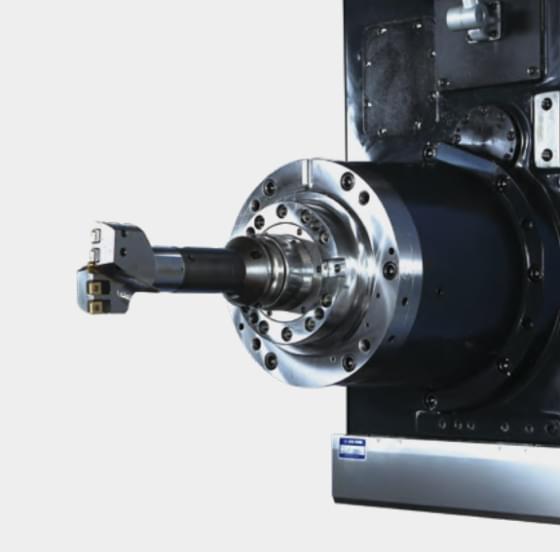

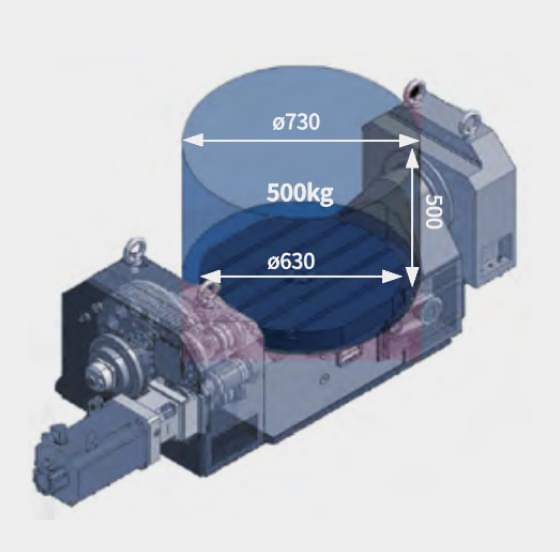

Various Components Various ComponentsCharacteristics of machining- High productivity

- Complex workpiece shape

- Precision parts

- Material: Steel, aluminum, titanium

High Speed Built-in Spindle Max. Spindle Speed

Max. Spindle Speed- 12000 / 20000 r/min

Good for high speed applications- Low centrifugal force

- Minimum heat generation

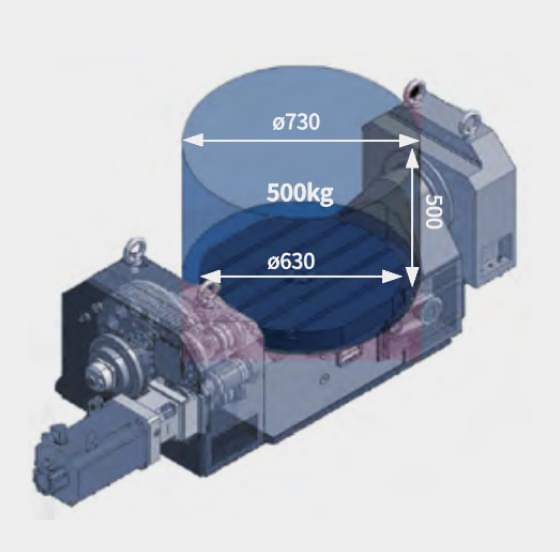

Response to Various size Workpieces Max.size

Max.size- Ø 730 x 500 mm

Max.Weight- 500 kg

From Big to Small- Machining a variety of workpieces by a single machine

-

Various Components Various ComponentsCharacteristics of machining- Guarantee productivity

- High rigidity

- High accuracy

- Material: Steel, aluminum, titanium

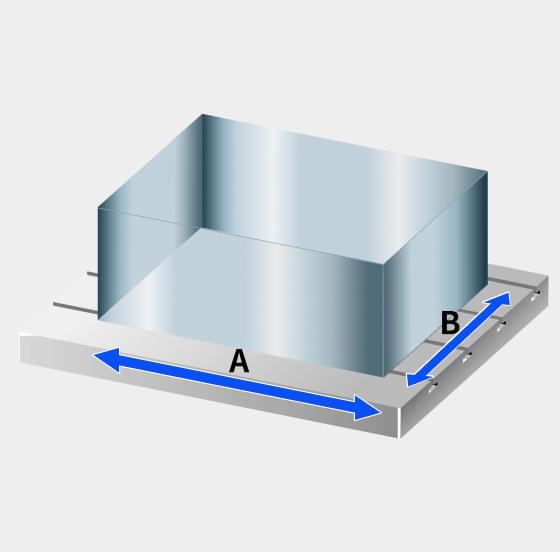

More Capacity Table Size (A x B)

Table Size (A x B)- DNM 4500S1000 x 450 mm

- DNM 5700S1300 x 570 mm

Max Weight on Table- DNM 4500S 600 kg

- DNM 5700S 1000 kg

High Speed Spindle for Productivity of DNM 4500S / 5700S Speed

Speed- DNM 4500S1000 x 450 mm

Feedrate(X/Y/Z)- X axis 42 r/min

- Y axis 42 r/min

- Z axis 36 r/min

Power- 11/18.5 kW

-

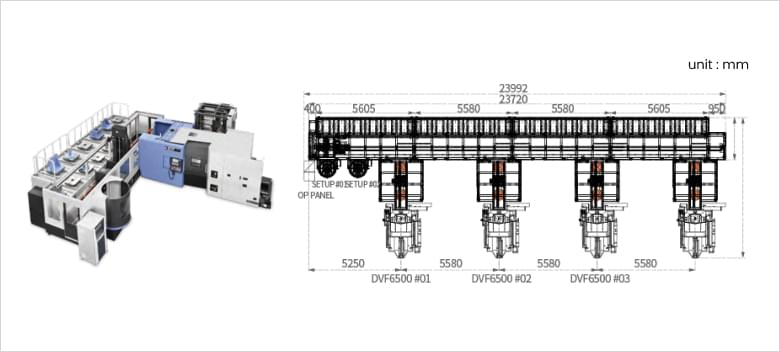

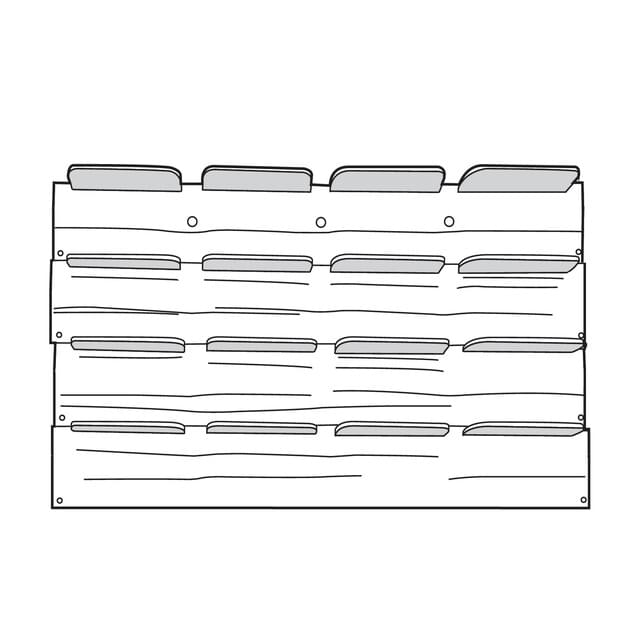

Various Aerospace Components Various Aerospace ComponentsCharacteristics of machining- LPS 5000

- Unmanned automation

- Machining various workpieces

- Material: various

LPS 5000 System

-

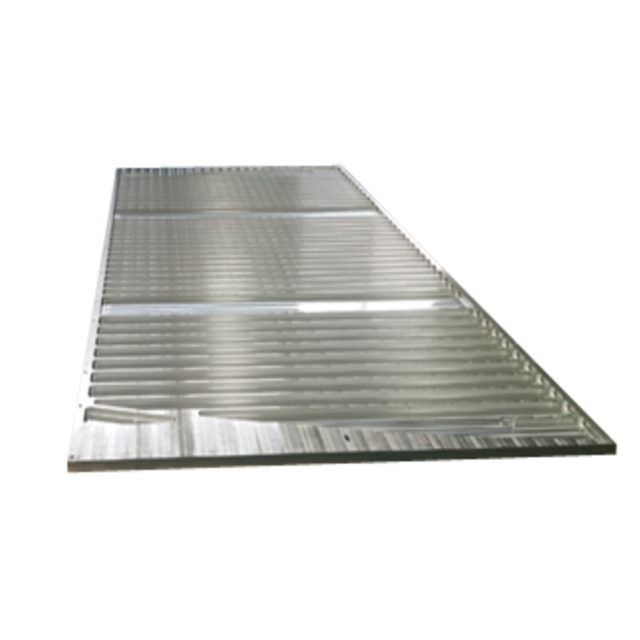

Wings, Ribs Wings, RibsCharacteristics of machining- High-speed spindle

- High volume chip disposal

- High productivity

- Material: aluminum

Spindle Max.spindle speed

Max.spindle speed- 30000 r/min

Max.spindle motor power- 75 kW

Tool shank- HSK A63

A-axis Tiling angle- +105 ~ -105

High-speed Scraper type Chip Conveyor Chip conveyor width

Chip conveyor width- 700 mm

Max.Removal Capa.- 7000 cm³/min

-

Clip Edge Frames Clip Edge FramesCharacteristics of machining- Hard-to-machine materials

- Powerful cutting

- Thermal compensation

- Material: Inconel

Machining ProcessSpecial Modifications- Maximized machining performance on customer request

Options- BALL SCREW / Bearing / Servo Motor

Spindle Torque

Coolant (Amount, Pressure)

Coolant (Amount, Pressure)- 25% Improved

Cutting (depth)- 50% Improved

Axis thrust- 20% Improved

Axis rigidity- 23% Improved

-

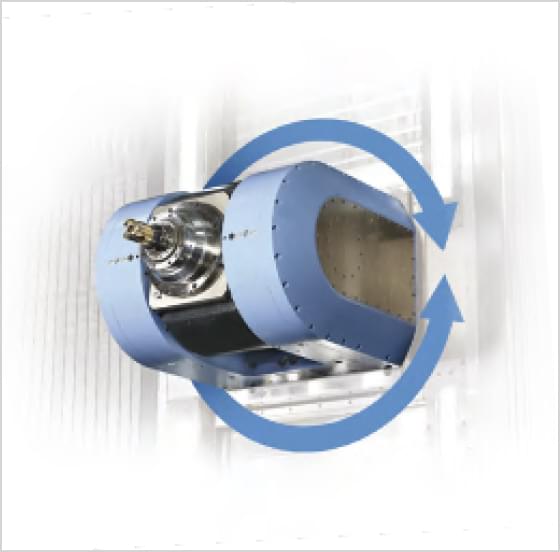

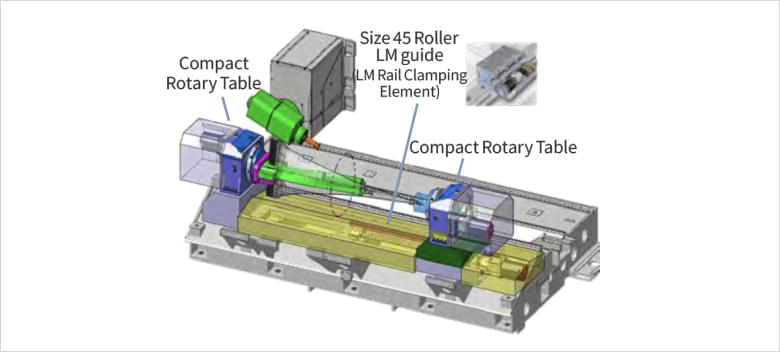

Large Aerospace Parts Large Aerospace PartsCharacteristics of machining- High-speed spindle

- 2-rotary table

- Multiple solutions

- Material: Various materials

Machine Structure

-

Frames FramesCharacteristics of machining- Guarantee productivity

- Heavy duty machine

- Material: titanium

Additional 4th Axis High Torque Spindle

High Torque Spindle Speed

Speed- 6000 r/min

Power- 26 kW

Torque- 825.9 N·m

-

In-flight Tanker Parts In-flight Tanker PartsCharacteristics of machining- High productivity

- Complex workpiece shapes

- Precision parts

- Material: CRES

High Speed Built-in Spindle Max.spindle speed

Max.spindle speed- 12000 / 20000 r/min

Good for high speed applications- Low centrifugal force

- Minimum heat generation

Response to Various size Workpieces Max.size

Max.size- Ø 730 x 500 mm

Max.Weight- 500 kg

From Big to Small- Machining a variety of workpieces on a single machine

-

Rib Supports Rib SupportsCharacteristics of machining- High productivity

- Large Working Area

- High Speed Machining

- Material: aluminum

For High-speed Machining Max.spindle speed

Max.spindle speed- 30000 r/min

Machining Process- 27500 r/min, 11050 mm/min

For Large Workpieces Table Size

Table Size- 3500 x 1850 mm

Max.Weight on Table- 10000 kg

-

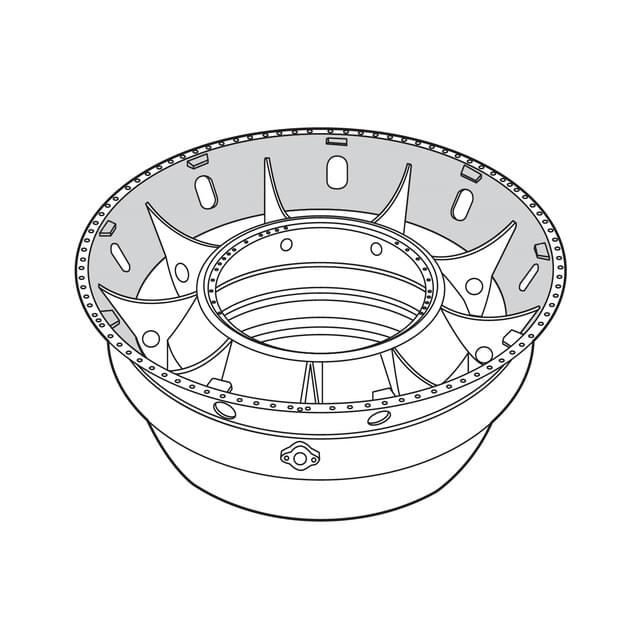

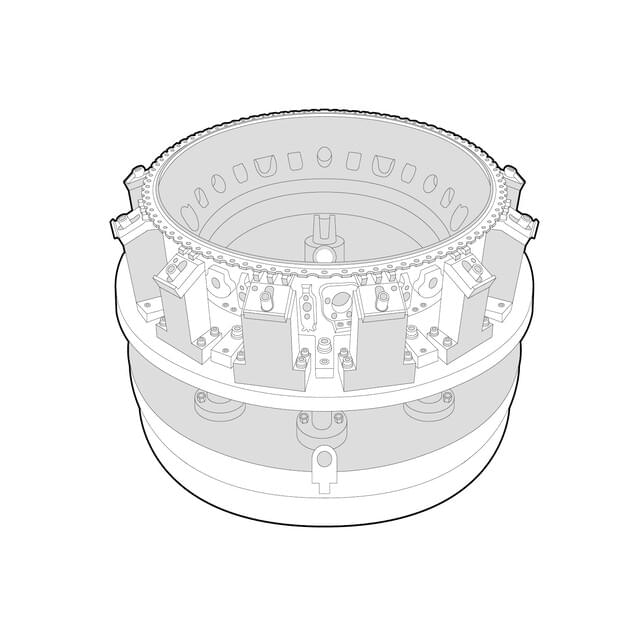

Engine Cases Engine CasesCharacteristics of machining- Highproductivity

- Highrigidity

- Strong RAM head

- Material: Inconel

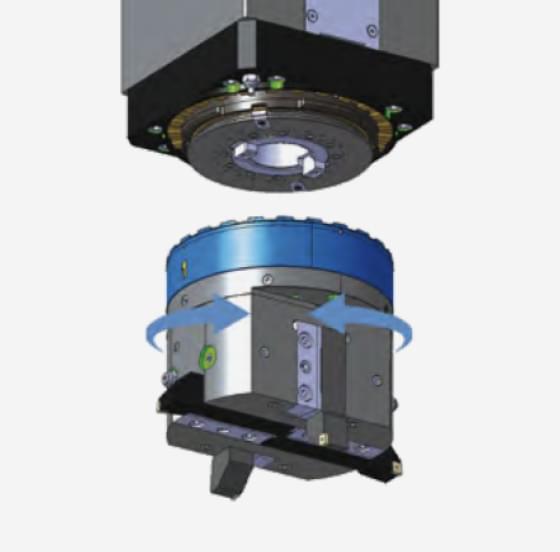

Unique Solution for Productivity of PUMA VTR Series Quad Tool Indexing

Quad Tool Indexing- 4 direction rotating head

- DMT has the patent

- Reduce tool change time

Strong RAM head of PUMA VTR Series

“Inconel is one of the most difficult materials to machine. But it’s easy to cut Inconel if you have the PUMA VTS Series. I will seriously consider further purchasing more PUMA VTS Series machines. “ –Engineer of E company

Clamping- 8 ton

Indexing- 90 deg

Max. Tool Length from Ram- 180 ~ 200 mm

-

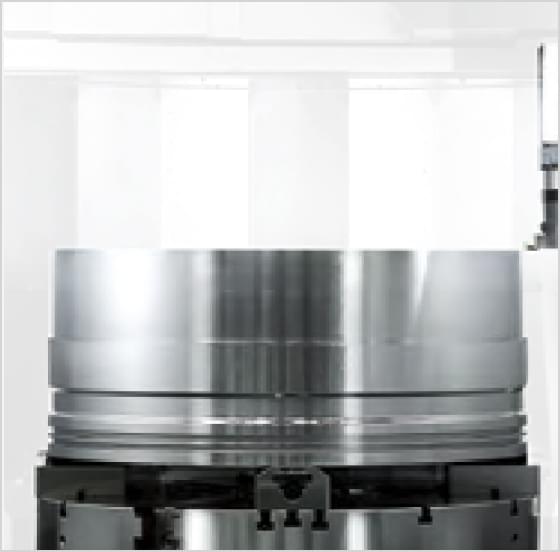

Engine Cases / Turbine Disks Engine Cases / Turbine DisksCharacteristics of machining- High accuracy

- High productivity

- Large capacity

- Material: Inconel / titanium

PUMA V8300-2SP Key Strengths in Turning Applications- Strong machine rigidity supports stablity despite long working hours. Can handle items with a diameter as long as 830mm (32.7 inch)

- PUMA V8300-2SP has independent motor systems in each of its spindles, so productivity can be enhanced by operating two spindles at once.

-

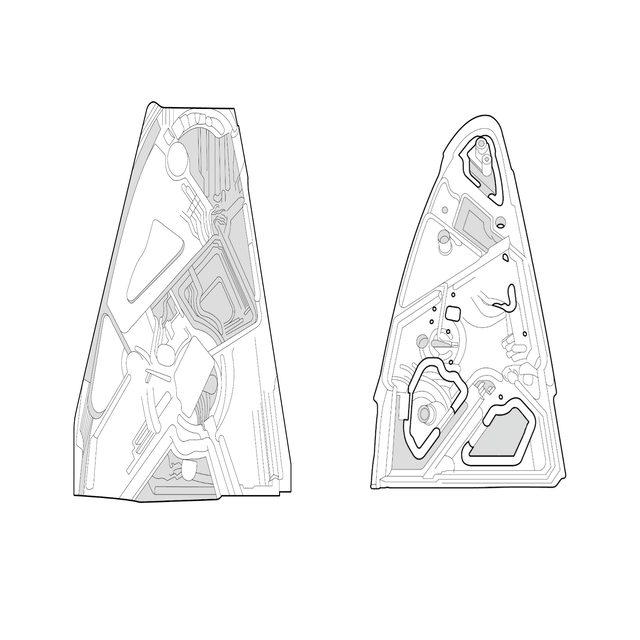

Engine Forward Cases Engine Forward CasesCharacteristics of machining- Turning function

- Reduced cycle times

- High torque spindle

- Material: Inconel / titanium

Turning table Rotaing speed

Rotaing speed- 500 r/min

Pallet size- Ø1000 mm

Intelligent Kinematic Compensation for 5-axis

- Minimize errors in complex 5-axis machining

- The tip of the tool is always in the correct position in relation to the workpiece

-

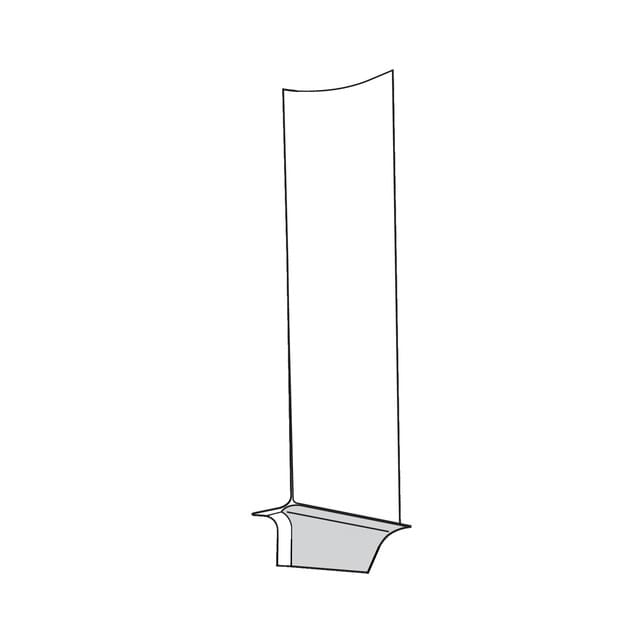

Engine Fan Blades Engine Fan BladesCharacteristics of machining- Guarantee accuracy

- High rigidity

- Curved shapes

- Material: aluminum

High Speed Built-in Spindle Max.spindle speed

Max.spindle speed- 12000 / 20000 r/min

Good for High Speed Applications- Low centrifugal force

- Minimum heat generation

Rotary Table Travels

Travels- A axis +30 ~ -120°

- C axis 360°

Rapid traverse- A axis 20 r/min

- C axis 30 r/min

-

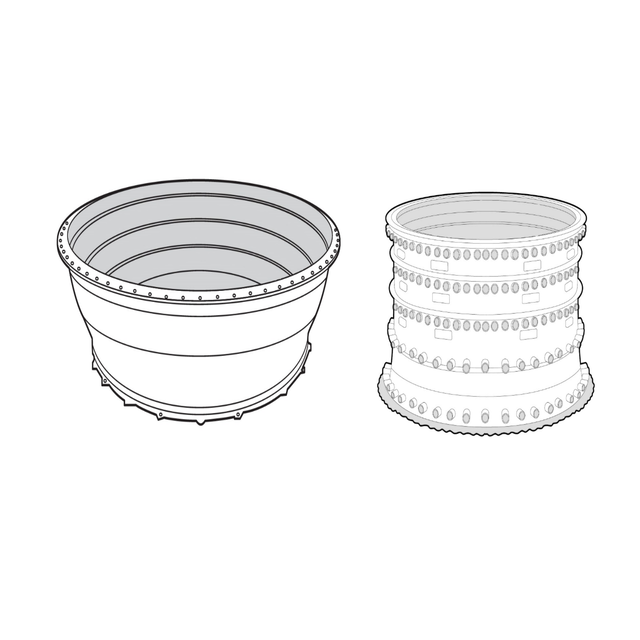

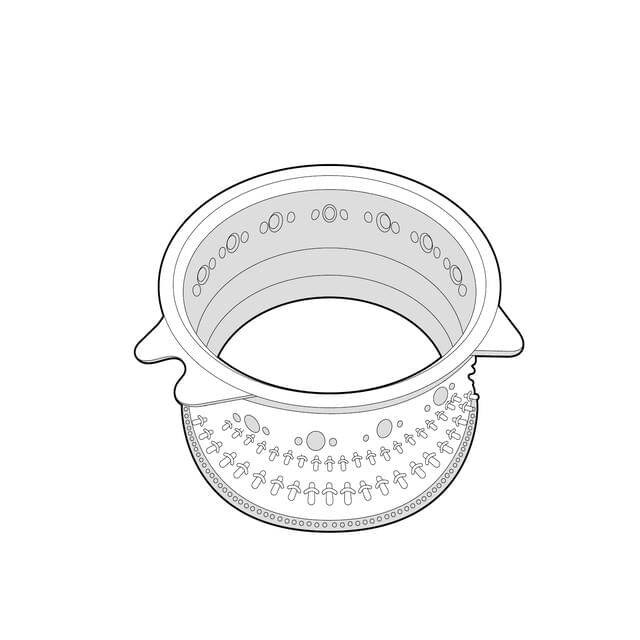

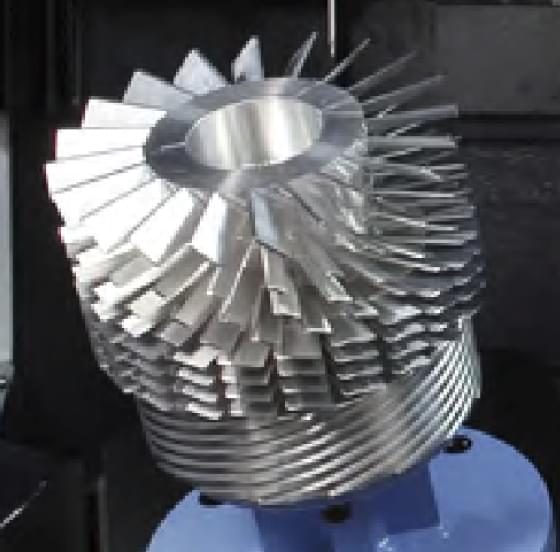

Geared Turbo Fans Geared Turbo FansCharacteristics of machining- Special spec.

- Continuous operation

- Auto compensation

- Material: Inconel

MachiningProcessCustomized- Custom machining of up to 800mm workpieces for special applications

Options- Angle head / Rotary table

- HSK-A63 / 100 tools

-

Rib Supports Rib SupportsCharacteristics of machining- Better accuracy

- Automation of applications

- Raise productivity

- Material: carbon steel

Automation Solution

DN Solutions’s customers

DN Solutions has solution for customers to get high accuracy,stability, safety required in the aerospace industry.

- Boeing, Pratt & Whitney, GE, Honeywell, M/S Aerospace, Kaydong, Infinisys, IDD, Moog, Kamatics, ES3…

- Mexico : Honeywell Mexico

- UK : Rolls Royce, AMRC (Partnership with UK dealer)

- France : Airbus, Safran, UTC systems

- Germany : Rolls Royce Germany

- Italy : Umbra, Ellena, Sicamel S.p.A., Ar.Ter. Srl, A. Abete Srl

- Turkey : HMS Makina, TEI Aviation, ALP Aviation, AYCAN Aviation, GE Turkey, Kale Pratt & Whitney, Roketsa

- China : GE China

- Korea : KAI, Hanhwa Techwin

- Singapore : Pratt & Whitney

- Indonesia : Pudak

- India : Polymech Industries