DN Solutions

Die & Mold Solutions

Die& Mold Solutions

DN Solutions provides solutions that help ensure precision, efficiency, and quality, which are key factors in mold manufacturing.

- Wealth of experience and know-how

We continuously improve and update our experience and know-how gathered From decades in the die/mold market

- The customer comes first

We always put our customers first by providing them with unique solutions designed to produce the best results under all conditions.

- Various Die&Mold solutions

The best solutions for various mold applications such as press / plastic / forging/ die casting

- Thorough whole-process management

We provide the best full-process service, ranging from pre-order qualification to on-time delivery with continuous consideration of customer needs, and comprehensive post-delivery services for die & mold solutions

Die& Mold Solution Reference

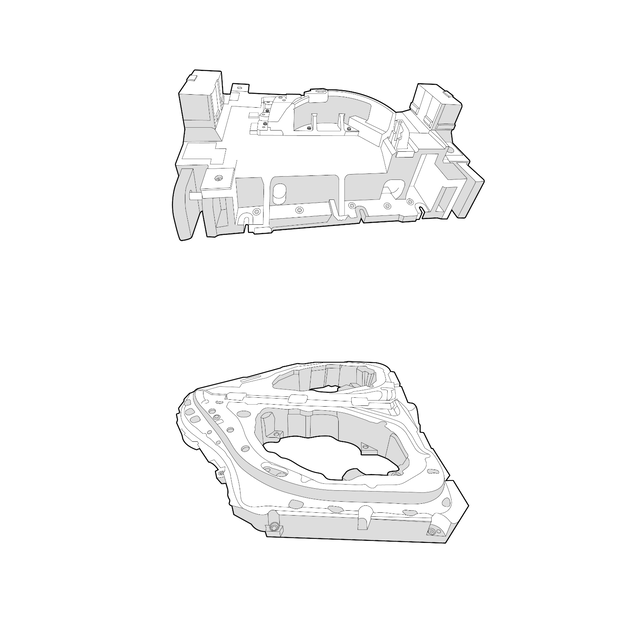

Dies & Molds are classified into plastic molds, press molds, die casting molds, forging molds, and other specialty molds depending on the application and the material of the molded product.

Plastic mold : Bumpers are made using plastic molds.

Forging mold : Crankshaft and other forging molds.

Die casting mold : Engines are made using diecasting molds.

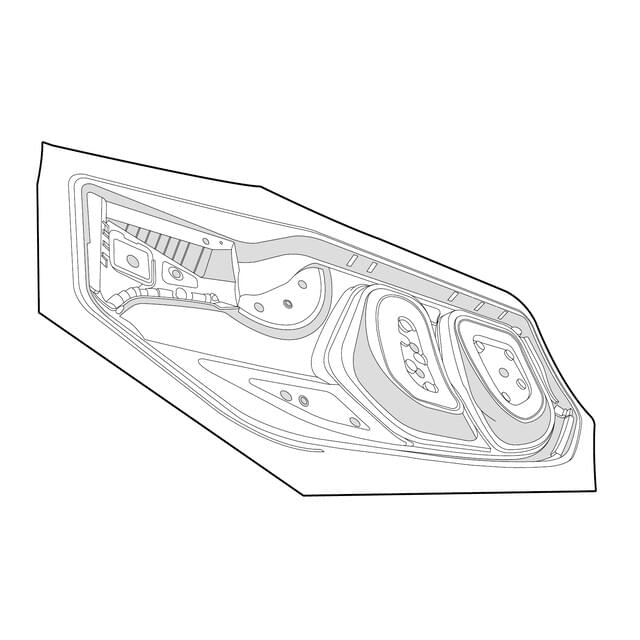

Press mold : Exterior of the cars body are made using Press die.

Specialist mold : Tires are made using other specialist molds.

-

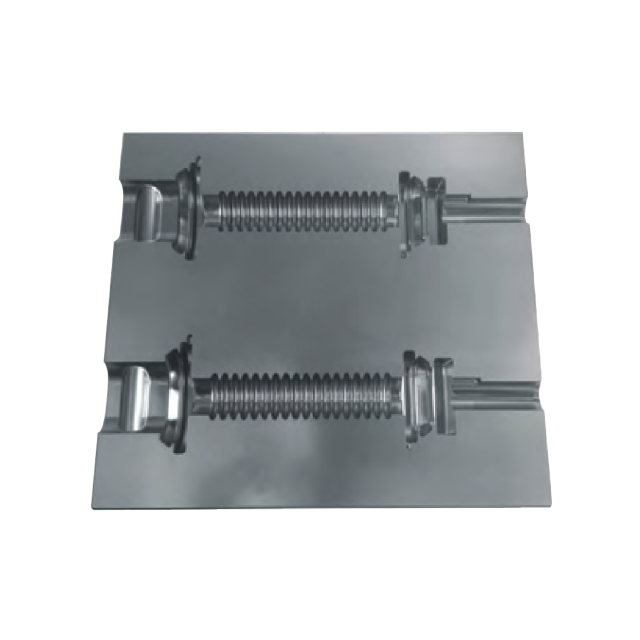

Hose Connectors Hose ConnectorsCharacteristics of machining- Smooth surfaces

- Material: HP4M (HRC32)

-

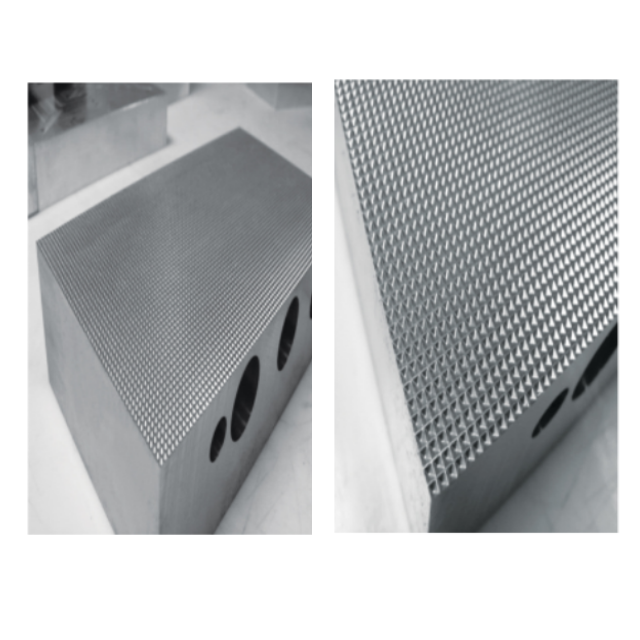

Embossing Pattern Embossing PatternCharacteristics of machining- Smooth surfaces

- Sharp edges

- Rigidity for Z axis

- Material: NAK80 (HRC40)

-

.png)

Tableware (Fork, Spoon..) Tableware (Fork, Spoon..)Characteristics of machining- Smooth surfaces

- High accuracy

- Profile tolerance 0.03mm

- Material: SKD11 (HRC 56)

-

-Crankshafts.png)

Crankshafts CrankshaftsCharacteristics of machining- Surface < Ra1.6

- High accuracy

- Profile tolerance: 0.1mm

- Material: 8NiCrMo (HRC58)

-

17”Wheels 17”WheelsCharacteristics of machining- Smooth surfaces

- Material: NAK80 (HRC 40), Chemical wood

-

Wheel Hubs Wheel HubsCharacteristics of machining- Smooth surfaces

- Material: SKD11

-

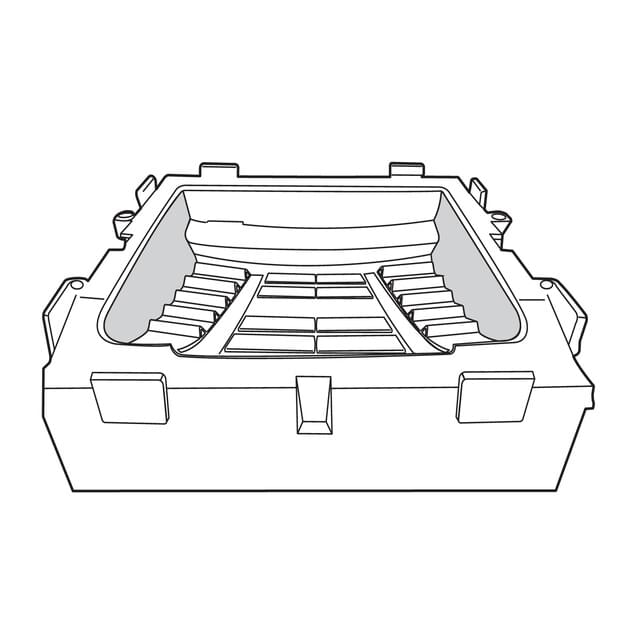

Transmission Cases Transmission CasesCharacteristics of machining- Smooth surfaces

- Material: SKD61 (HRC 56)

- Profile Tolerance 0.03mm

-

Automotive Die Castings

-

-Roof-Punches.png)

Roof Punches Roof PunchesCharacteristics of machining- Smooth surfaces

- Material: GC200

-

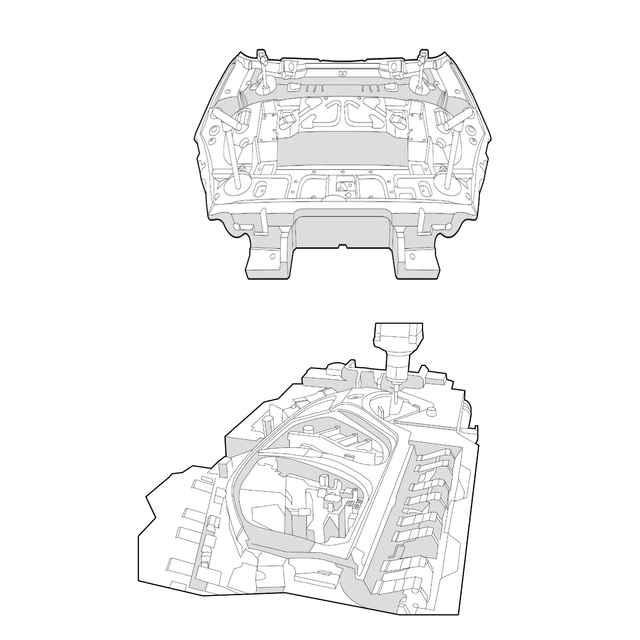

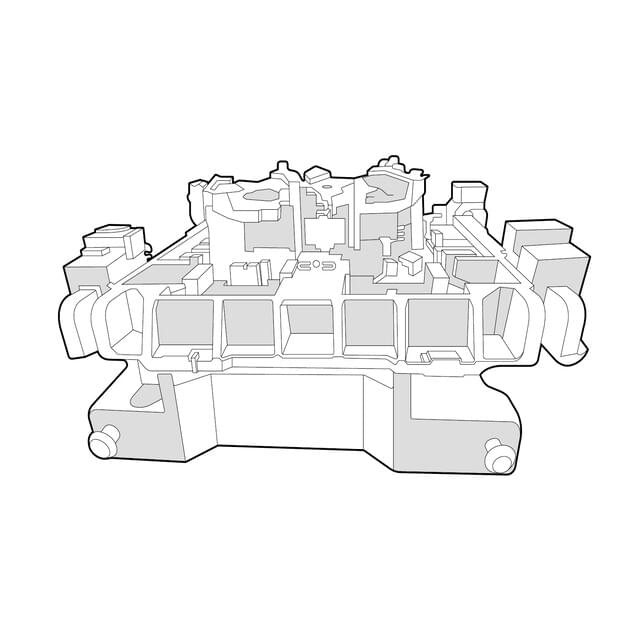

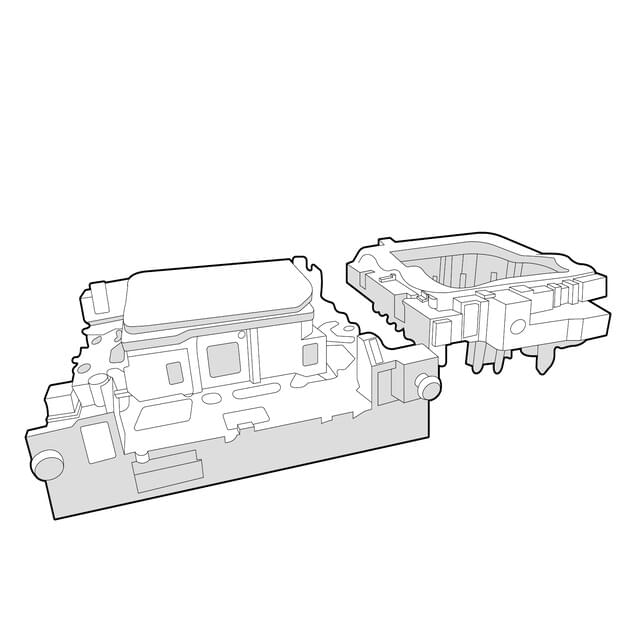

Automotive Press -

Automotive Press -

Automotive Press -

Automotive Press -

Automotive Press -

Automotive Press

-

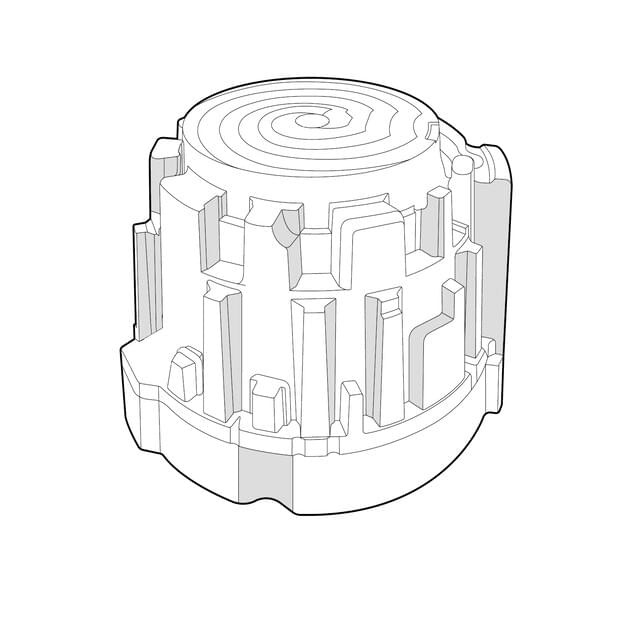

Tire Molds Tire MoldsCharacteristics of machining- Smooth surfaces

- Material: Steel, chemical wood, aluminum

DN Solutions Die& Mold Technology

DN Solutions' Die& old technology provides optimal solutions by applying DSQ, DAFC, and DHC.

- DSQ : DN Solutions Super Quality

High speed/ high ccuracy contouring control function

- DSQ 1: AICC II (400 block), Machining Condition Selection (R0, R1~R10 step)

- DSQ 2: AICC II( 400 block), Machining Condition Selection (R0, R1~R10 step), Data Server 1GB

- DSQ 3: AICC II (600 block), Machining Condition Selection (R0, R1~R10 step), Data Server 1GB

DSQ PACKAGE

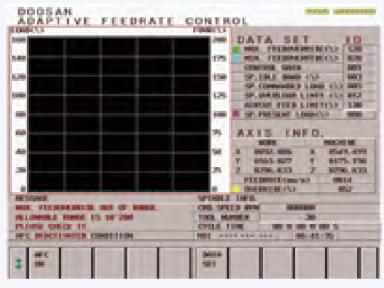

- DAFC : DN Solutions Adaptive Feed Control

Optimal feed control function

- Controls the feedrate to maintain low cutting load

AFC System

- Summary

- Based on the real-time spindle load detection, it calculates the optimal feedrate

- Goals

-

Maximized

productivityReduced

costsMinimized

damage

of tools,

parts

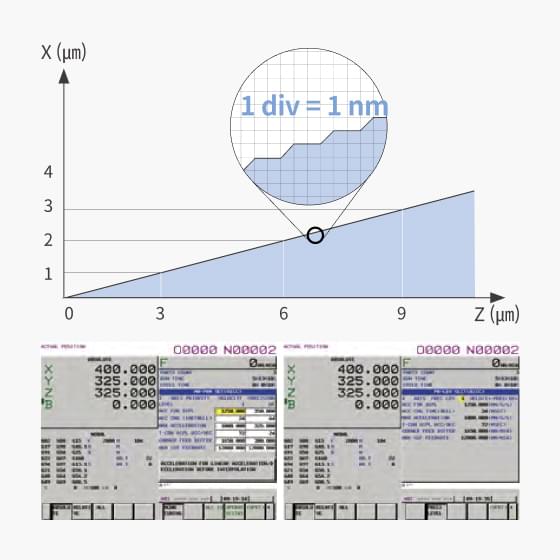

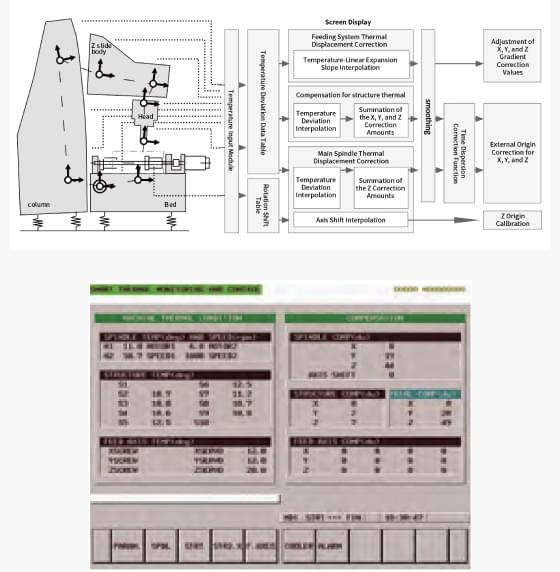

- DHC : DN Solutions Heat Compensation

Thermal displacement compensation function

- Spindle compensation

- Structure compensation

Thermal Displacement Compensation System

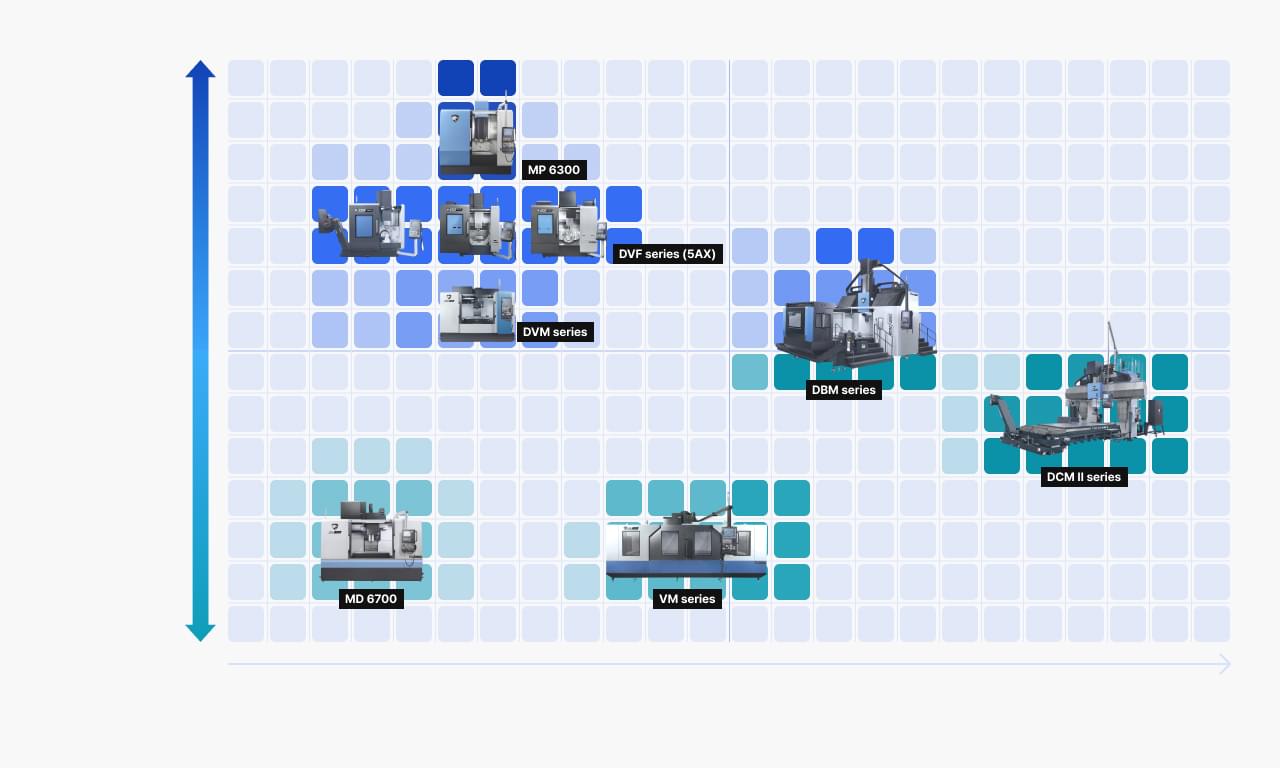

Die & Mold Product Line-up

DN Solutions’ mold technology utilizes optimal solutions to provide more efficient, stable, and various line-up.

.png)

.png)