加工解决方案

迪恩解决方案为产品生产提供轻松易懂的最佳加工流程和专业化加工解决方案。

-

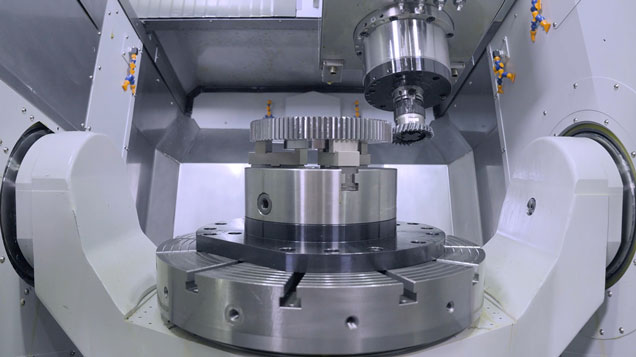

INVO MILLING

使用InvoMilling工具及五轴加工机床加工外齿轮及花键,并用同一工具加工出不同module的齿轮廓线的解决方案

-

刮齿

通过主轴(工作台)和铣削主轴的同步控制,加工内/外径精密齿轮的解决方案

-

在车床设备上进行倾斜面加工的功能

在具备铣削功能的车削中心设备上,通过变换加工坐标系解决斜面加工问题的解决方案

-

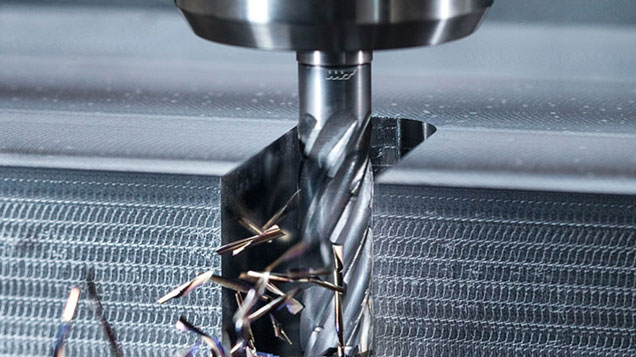

次摆线切削

将原来由CAM编写的Trochoidal加工,通过基于Macro的Cycle开发,使用户易于使用的解决方案

-

加工条件选择功能

为了提高模具加工面的品质和生产效率,各设备可以选择最优参数的解决方案

-

.jpg)

DSSV

DNSolutions Spindle Speed Variation

-

.jpg)

-

5轴机车削功能

为五轴机床提供车削功能以适用复合工序的解决方案

-

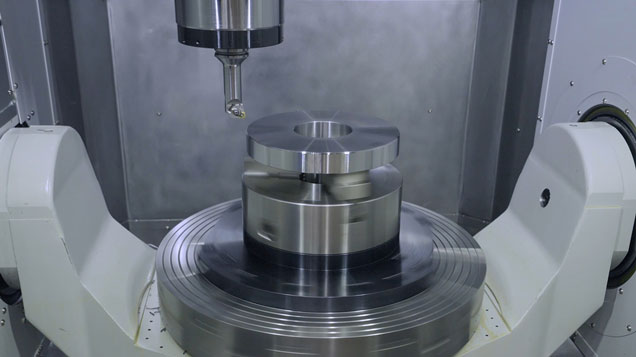

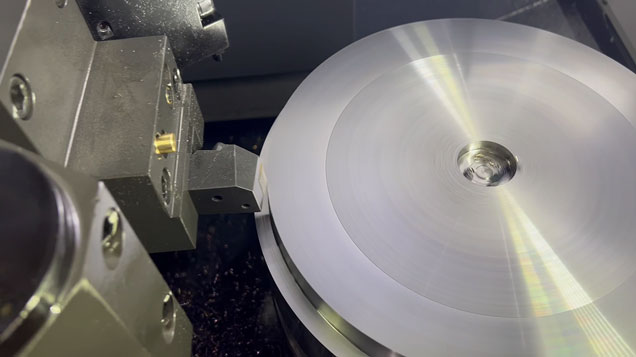

硬车削加工

使用CBN等高硬度工具,对Hrc45以上的高硬度材料,实施最优化旋削加工的解决方案

-

HFP 1540操作数据包

为了设备性能的可靠性和客户的便利性,确认HFP1540 Performance,提供基于Post works的Post processing/ Simulation Machine File解决方案

-

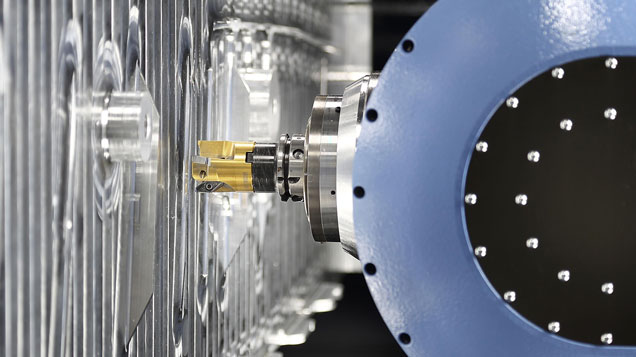

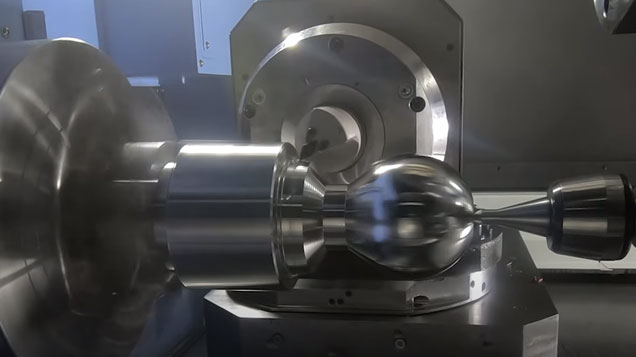

自由车削加工

不同于使用各种Tool加工不同形状工件的现有车削加工,使用1个Tool的主轴旋转控制加工方式的解决方案

-

三重补偿加工

实现蝶阀加工需求市场要求的偏心锥体加工的解决方案