DN Solutions

Automotive & Electric

Vehicle Solutions

Automotive Solutions

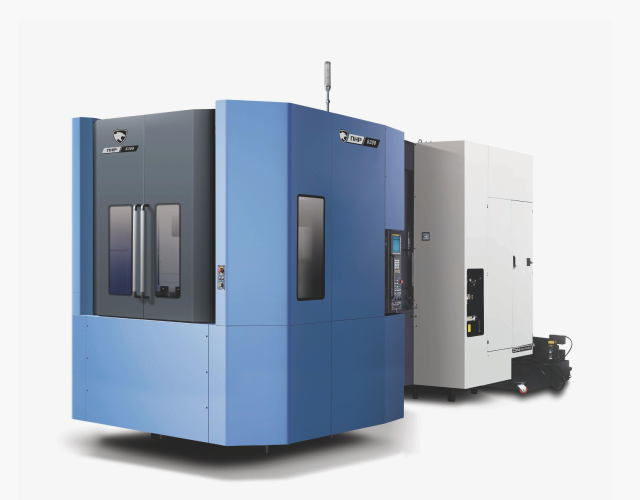

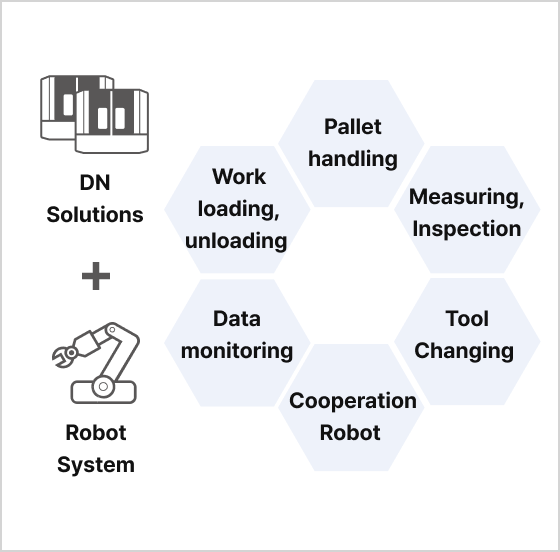

DN Solutions helps customers in the automotive industry efficiently manufacture and ensure component quality and reliability, while also providing integrated robotics and highly automated solutions.

- Wealth of experience and know-how

Our vast databases, which are based on the experience and know-how accumulated by our system engineers at home and overseas over several decades, enable us to continuously provide turn-key solutions to meet our customers’ requirements.

- The customer comes first

We always put our customers first by providing

them with unique solutions designed to produce

the best results under all conditions. - Experts at home and abroad

Thanks to their consummate professionalism and

teamwork, our system solutions team responds

promptly to customers’ technical requirements,

executes diverse projects, and operates an advanced

technical infrastructure to provide the most

efficient solutions to all our customers. - Thorough whole-process management

We provide the best full-process service, ranging from pre- order qualification to on-time delivery with continuous consideration of customer needs, and a comprehensive post-delivery service.

Electric Vehicle Solutions

When it comes to manufacturing electric vehicles involving innovative technologies and complex components, DN Solutions can help manufacture precision parts, machine and apply new materials, and can provide solutions for efficient manufacturing and quality assurance.

- The customer comes first

We always put our customers first by providing them with unique solutions designed to produce the best results under all conditions.

- Wealth of experience in the automotive industry

We can provide best solution for the EV industry based on our substantial experience in automotive industry

- Dedicated engineering team for the EV industry

DN Solutions has prepared a special applications engineering team for EV from the early stage of the industry

- Thorough whole- process management

We provide the best full process service, ranging from pre-order qualification to on time delivery with continuous consideration of customer needs, and comprehensive post-delivery services

Automotive Solutions

Optimal machining solutions for various parts of internal combustion and electric vehicles

PE System(Power Electric System) :

New power system that replaces combustion engine

Motor housing,supports, inverters ,reducers, etc.

Retained Equipment :

Co-existing equipment in gasoline& iesel cars and EV

Thermal systems,steering,axle drive, suspension ,brakes, etc.

Battery :

New power system that replaces fuel tank

Battery pack cases, control boxes ,end plates , etc.

-

_Motor-housing.jpg)

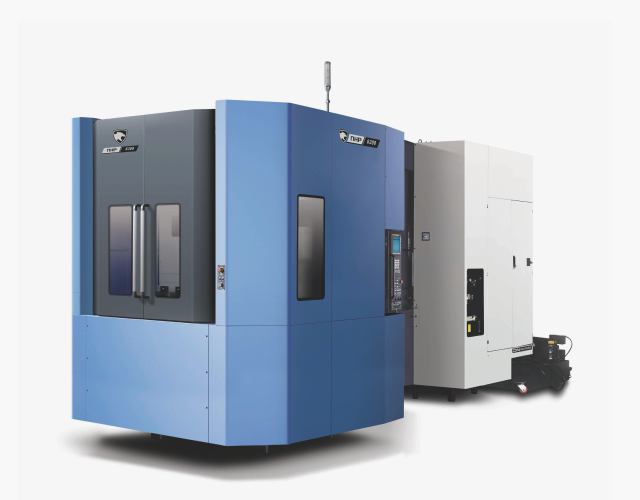

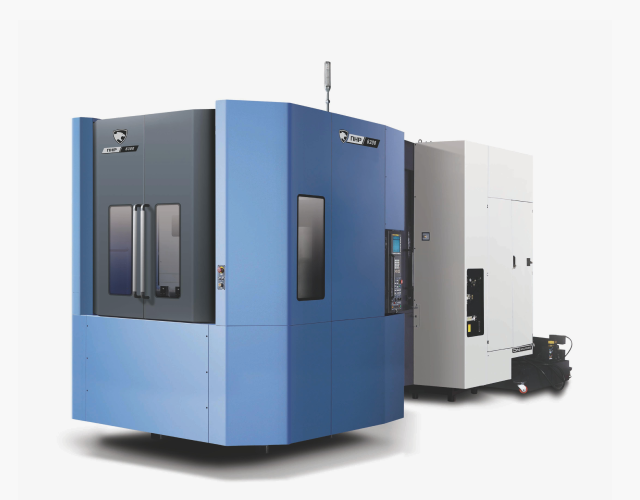

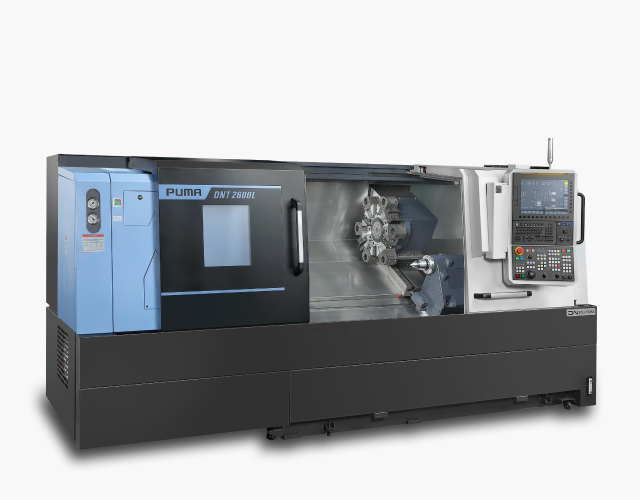

MOTOR HOUSING Spindle Max. spindle speed

Max. spindle speed- 15000/15000/20000 r/min

Max. spindle motor power- 30/37/37 kW

Max. spindle motor torque- 230/303/221 N·m

High rigidity, high Speed

3-point support high rigidity bed

3-point support high rigidity bed- Easy to install and maintain accuracy

Step guided column- High Rigidity, High Speed

-

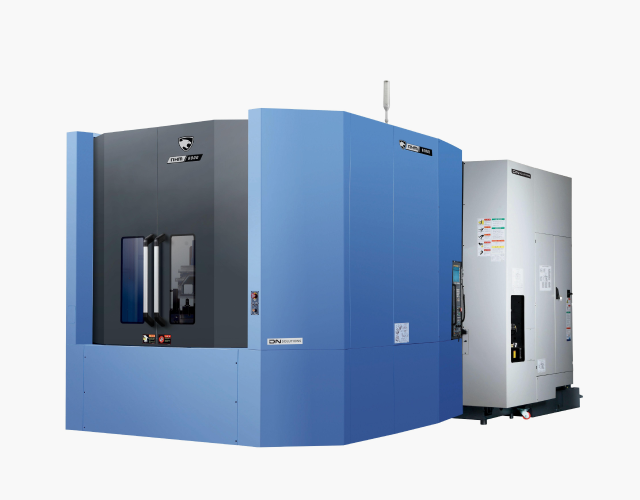

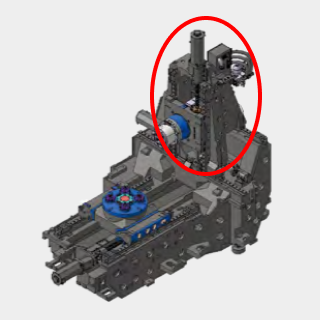

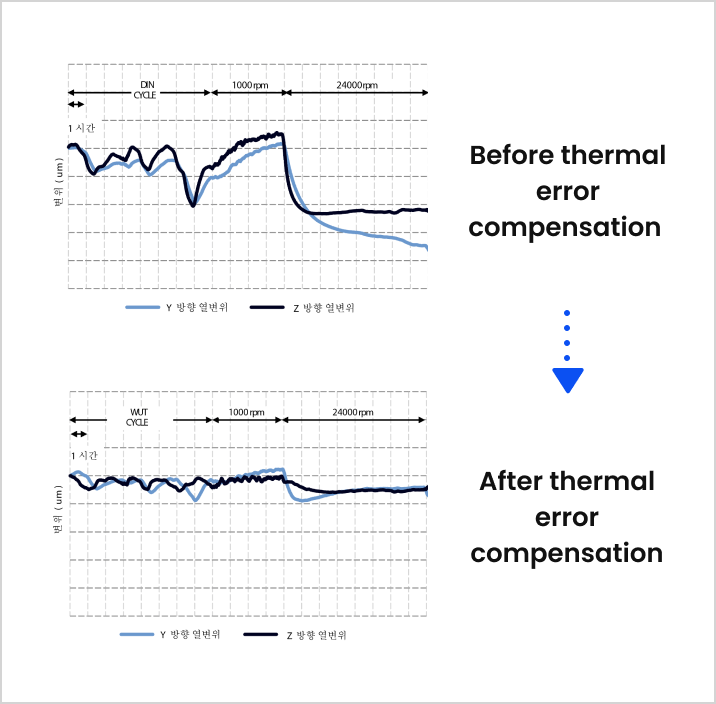

MOTOR HOUSING COVERS New, High-Precision Spindle Max. spindle speed

Max. spindle speed- 12000/24000 r/min

Spindle Thermal Error

Compensation System(standard)

Thermal error of the spindle is calculated with the spindle temperature feedback and automatically compensated to maintain the highest level of work accuracy.

-

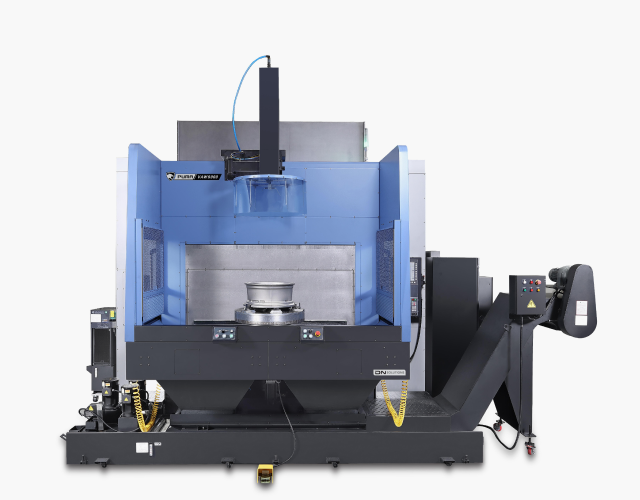

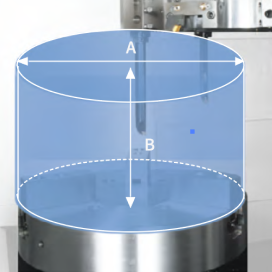

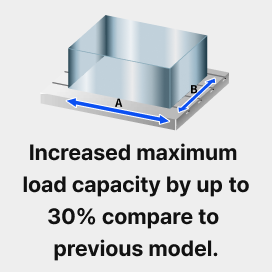

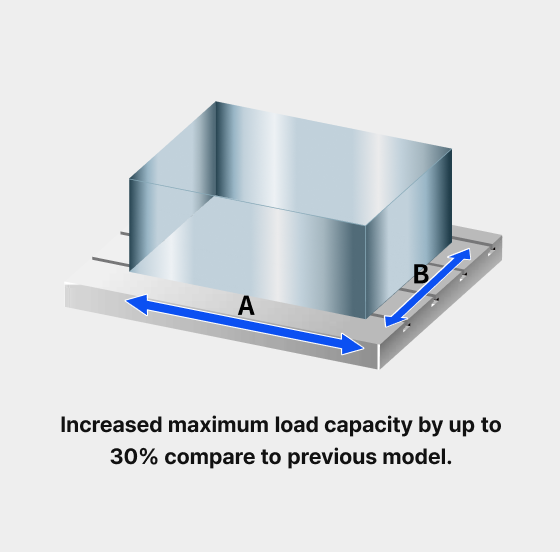

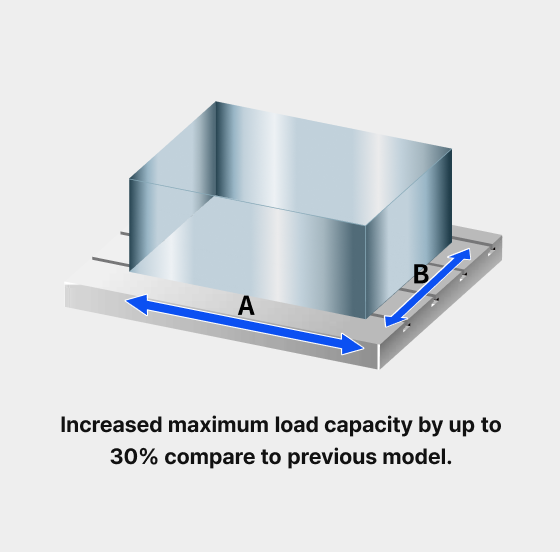

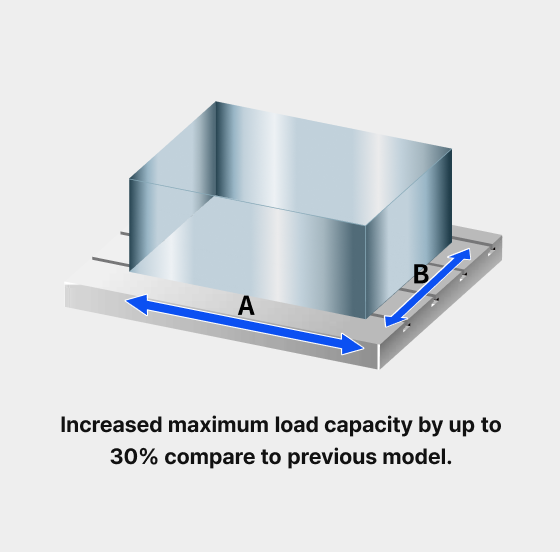

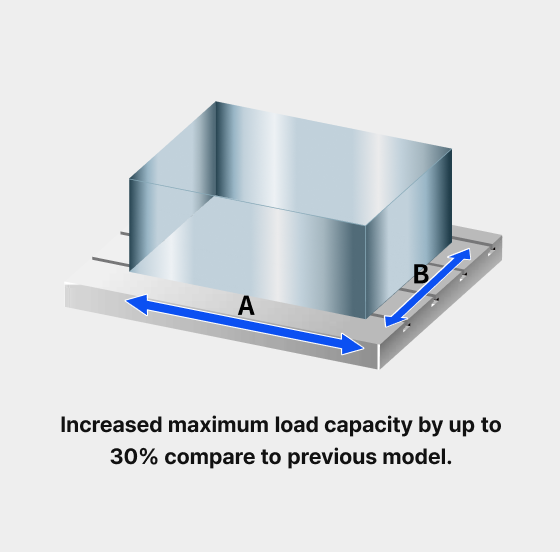

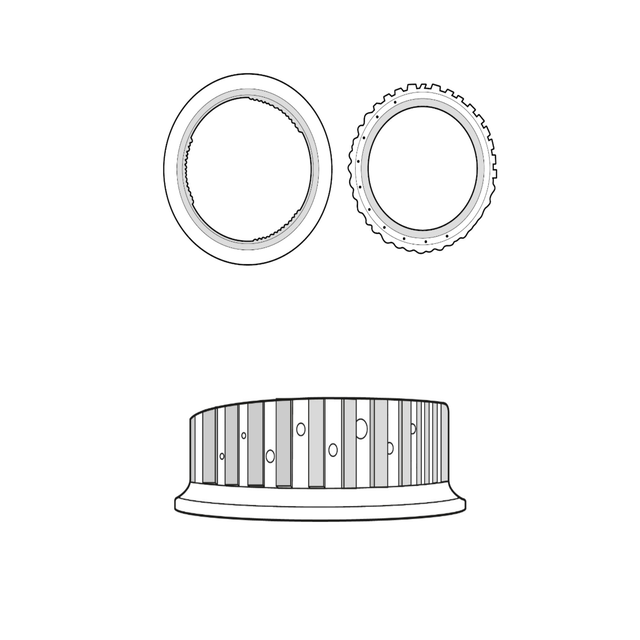

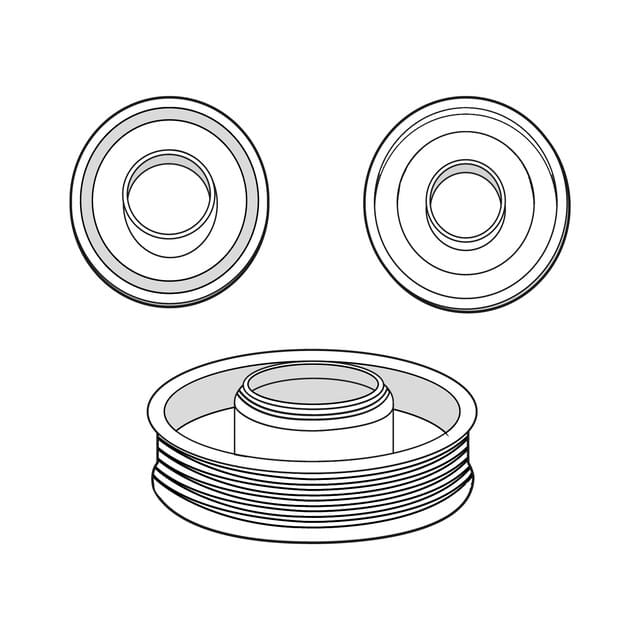

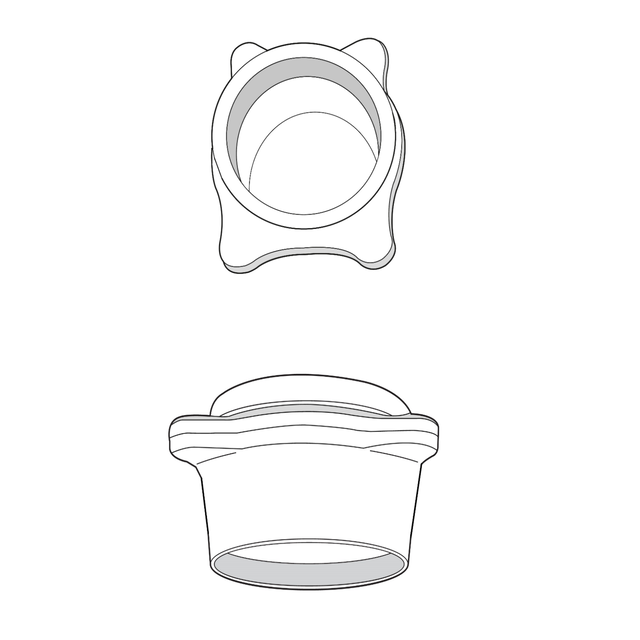

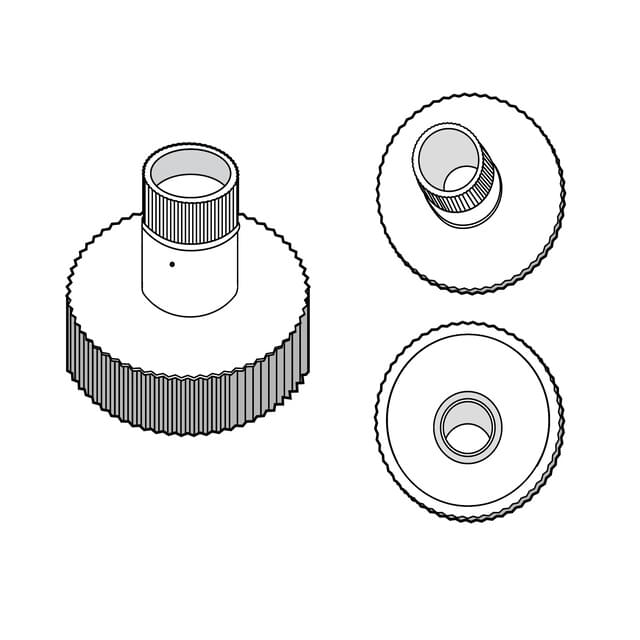

SUPPORT RINGS Wide Machining Area

Table size(AxB)

Table size(AxB)- DNM 4500/L 1000{1050} x

450 mm - DNM 5700/L 1300{1500} x

570 mm - DNM 6700/L/XL 1500{1600/2200}

x 670 mm

Max. turning diameter(A)- PUMA V400/V400M Ø496/420

mm

Max weight on Table- DNM 4500/4500L 600 kg

- DNM 5700/5700L 1000 kg

- DNM 6700/6700L/6700XL

1300 kg

Max. turning length(B)- PUMA V400/V400M 461/400 mm

- DNM 4500/L 1000{1050} x

-

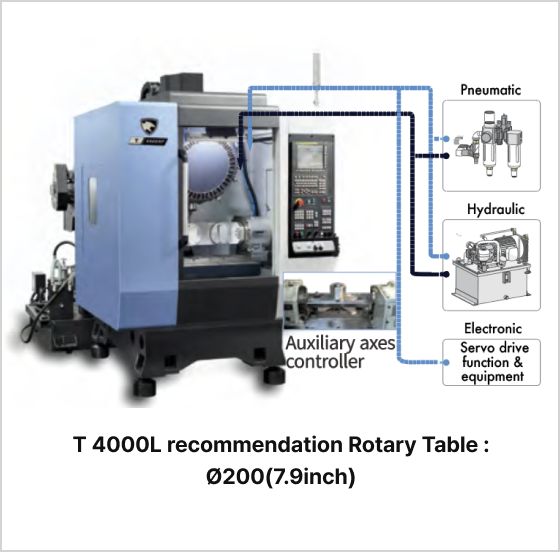

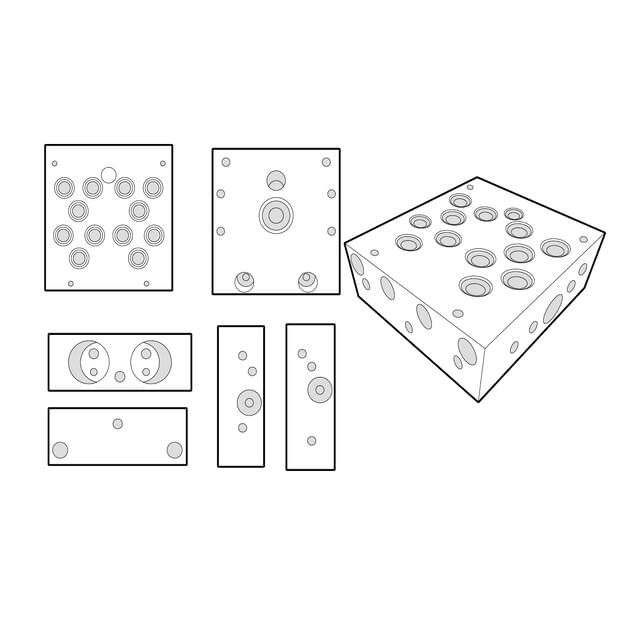

INVERTER CASES Optimal Design for the

User Environment

Optimal Design for the User Environment Specification T4000 T4000L Width 1600mm 2050mm Length 2560mm 2574mm Height 2324mm 2324mm Distance to table 799mm 799mm - The machine's compact design delivers

greater user convenience and requires

minimal floor space.

Wide machining area Table size (AxB)

Table size (AxB)- DNM 4500/L 1000{1050} x 450 mm

- DNM 5700/L 1300{1500} x 570 mm

- DNM 6700/L/XL 1500{1600/2200} x 670 mm

Max weight on table- DNM 4500/4500L 600 kg

- DNM 5700/5700L 1000 kg

- DNM 6700/6700L/6700XL 1300 kg

- The machine's compact design delivers

-

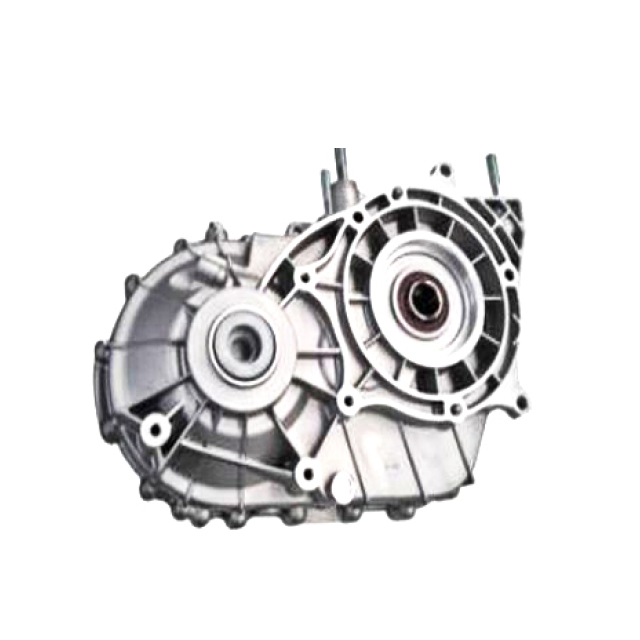

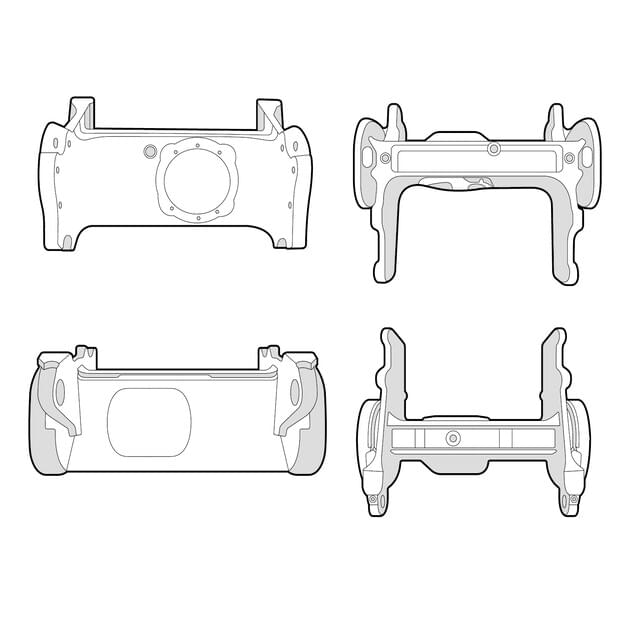

MOTOR REDUCER HOUSINGS Wide machining area Table size(AxB)

Table size(AxB)- DNM 4500/L 1000{1050} x 450 mm

- DNM 5700/L 1300{1500} x 570 mm

- DNM 6700/L/XL 1500{1600/2200} x 670 mm

Max weight on Table- DNM 4500/4500L 600 kg

- DNM 5700/5700L 1000 kg

- DNM 6700/6700L/6700XL 1300 kg

Spindle Max. spindle speed

Max. spindle speed- 8000/12000/15000 r/min

Max. spindle motor power- 18.5 kW

Max. spindle motor torque- 117.8 N·m {8000/12000/15000 r/min}

- 286 N·m {8000 r/min high torque version}

-

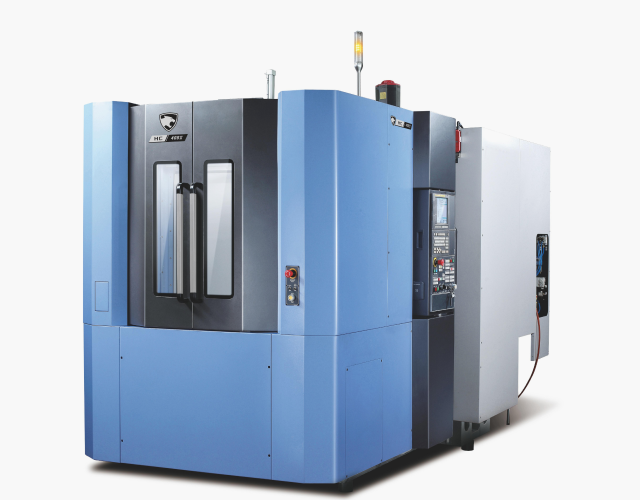

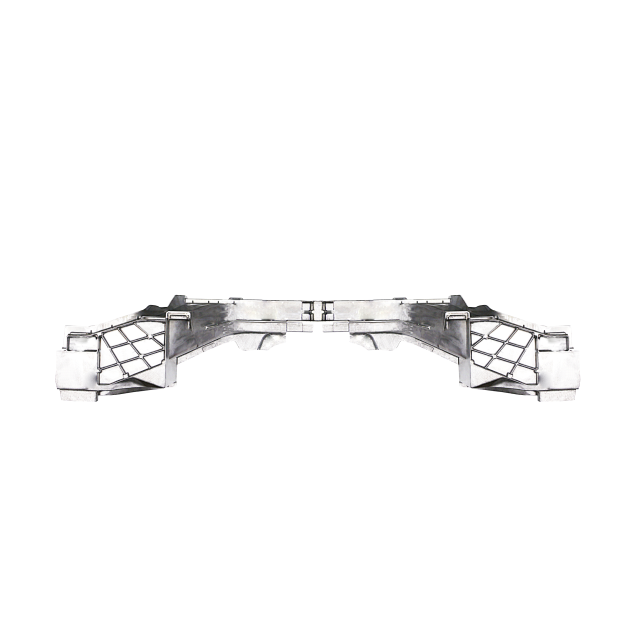

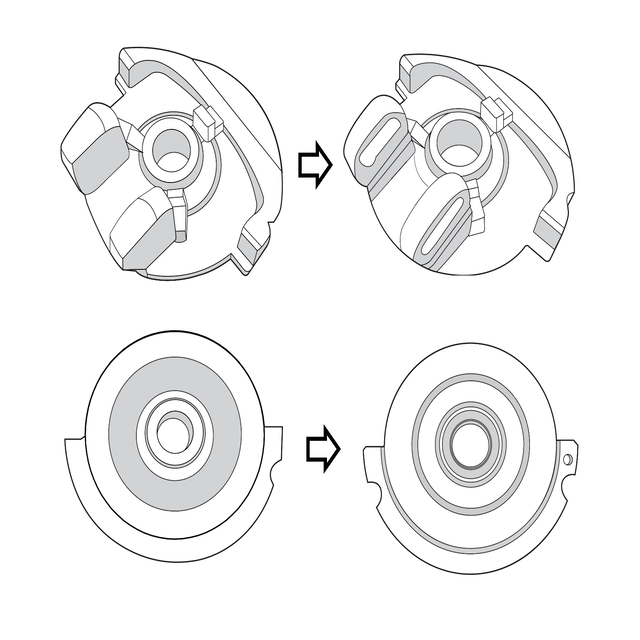

MEMBER Dual Rotary Table Solution Operational flexibility

Operational flexibility- Capable of controlling the two A axes

- either simultaneously or individually

- Additional 6th Axis (Addition of an axis to the 5 axes : Control Opt.)

Reduced investment cost- 2 machines ⇀ a single machine

Improved operating stability- Improved jig rigidity and smooth chip evacuation by applying a special bed

-

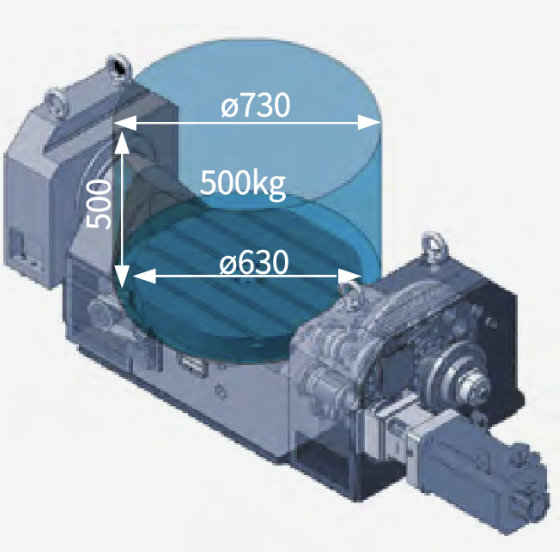

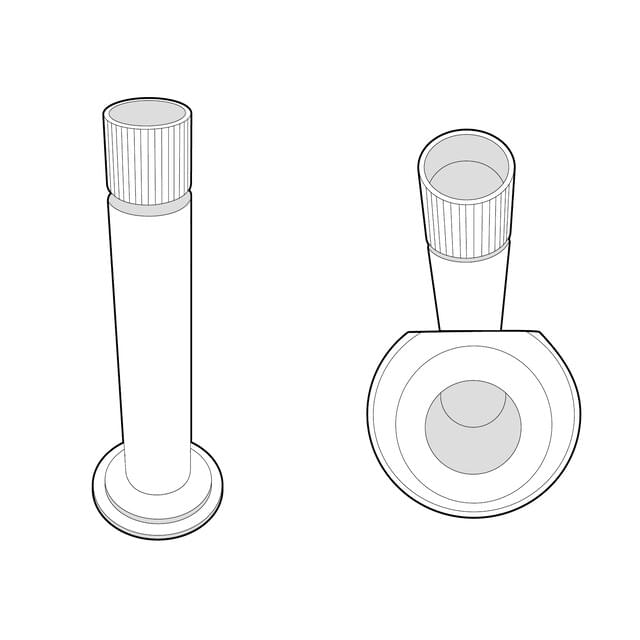

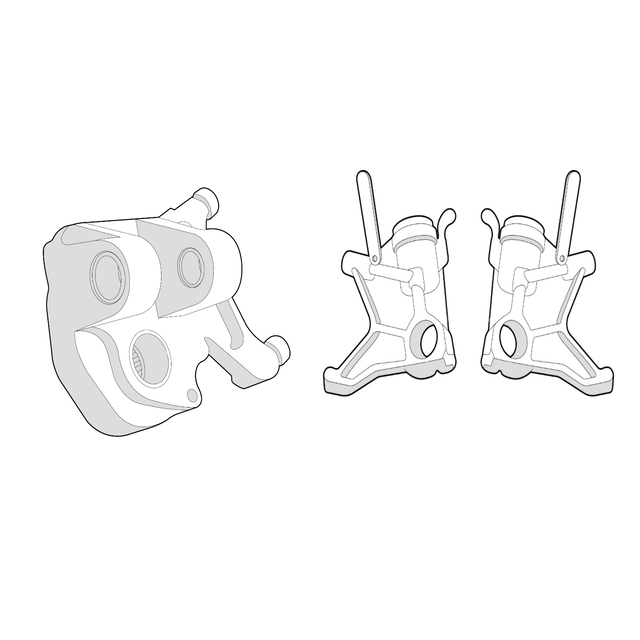

SHOCK TOWERS Spindle

Built-in motor minimizes vibration and noise generated

Max. spindle speed- 12000{2000}/3000 r/min

Rotary Table

Large workpiece capacity allows a variety of parts to be machined in one set up

Max. Workpiece Size- Ø 730 x 500 mm

Max. weight- 500 kg

-

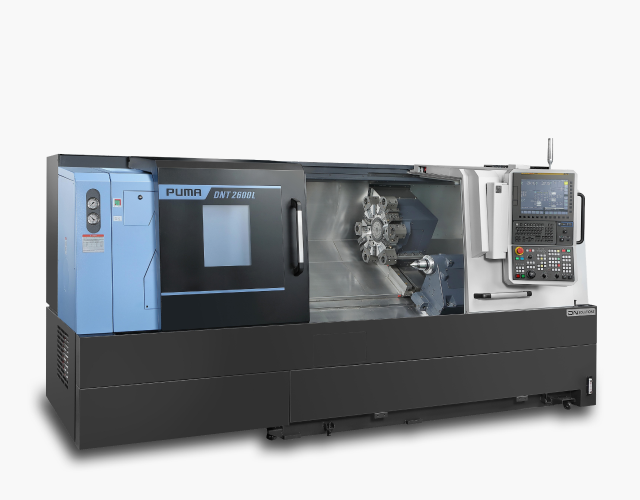

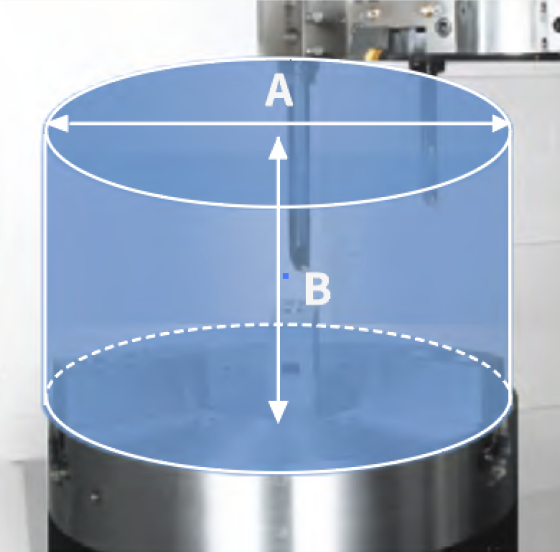

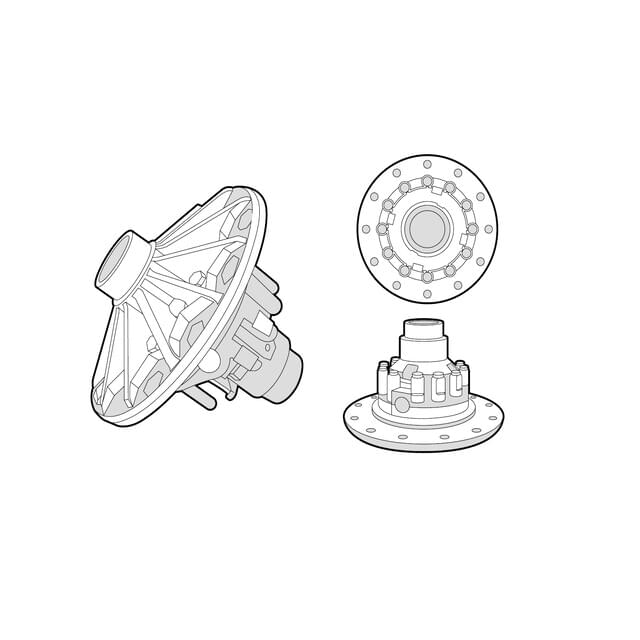

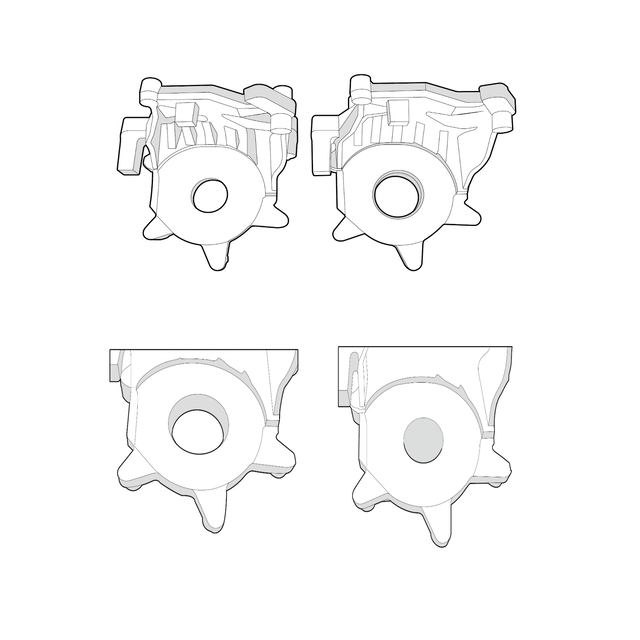

DIFF GEAR HOUSINGS Machining area Max. turning diameter (A)

Max. turning diameter (A)- PUMA V400(P) / MØ496 / 420 mm

Max. turning length (B)- PUMA V400(P) / M461 / 400 mm

4th-axis rotary table

The compact high-precision, highly rigid design enables vertical and horizontal use, and delivers a strong clamping force.

-

BEARING SUPPORTS

-

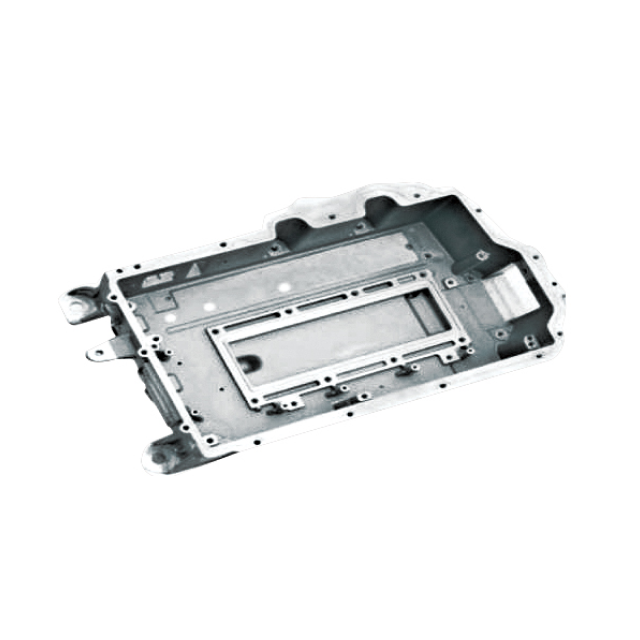

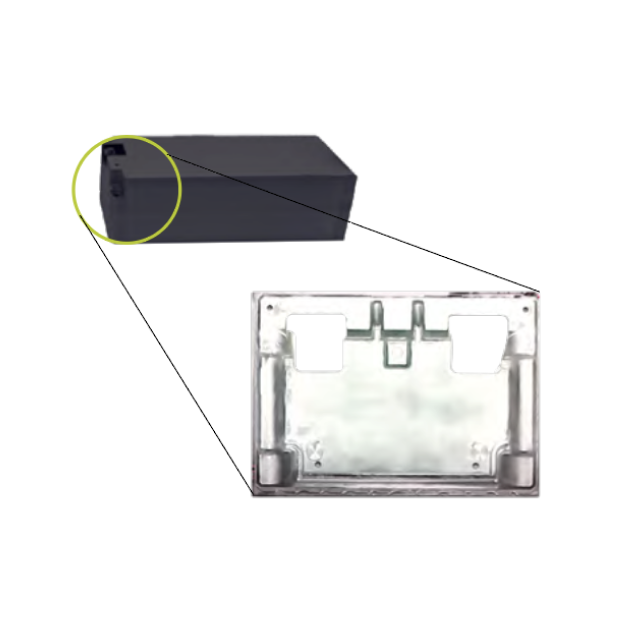

END PLATE 4-axis Auxiliary Device Interface/

Hydraulic & Pneumatic Jig Line

-

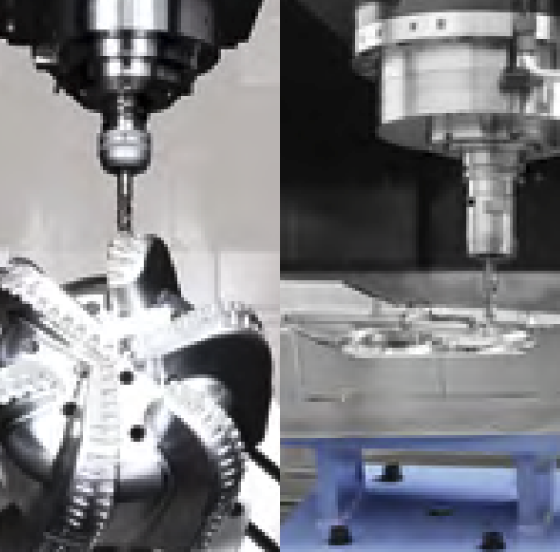

MODULE CASES New, High-Precision Spindle

The spindle length has been minimized to reduce the time required for acceleration/ deceleration and idle time, resulting in greater productivity and reduced vibration and noise

FANUC 31i

The FANUC 31i is designed to satisfy users' demands for higher machining accuracy and ultra-fine cutting.

Maximize productivityMaximize productivity table Description Unit FANUC 31i Rapid traverse m/min 48 -

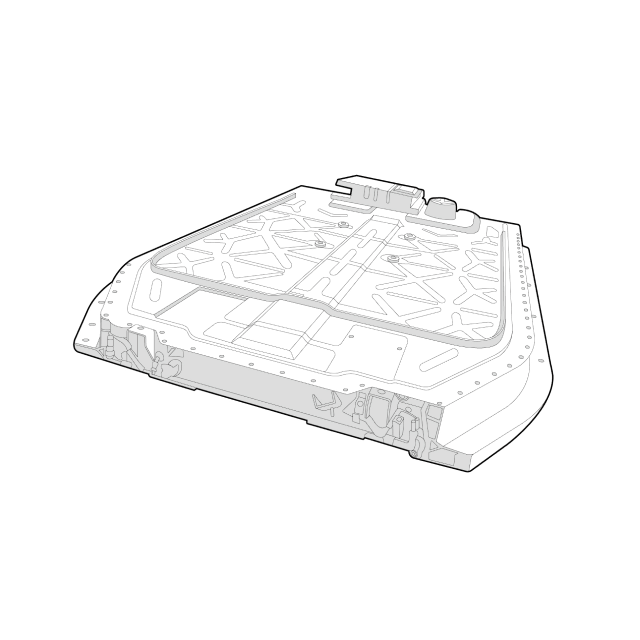

BATTERY PACK CASES High Precision Through S/W

Tool load monitoring

Tool load monitoring- During cutting operation, abnormal load caused by wear and tear of the tool is detected and an alarm is triggered to prevent further damage.

Thermal compensation function- A thermal error compensation function is provided as a standard feature to secure stable cutting safe from potentially harmful environmental factors.

Wide machining area Table size(AxB)

Table size(AxB)- DNM 4500/L 1000{1050} x 450 mm

- DNM 5700/L 1300{1500} x 570 mm

- DNM 6700/L/XL 1500{1600/2200} x 670 mm

Max weight on Table- DNM 4500/4500L 600 kg

- DNM 5700/5700L 1000 kg

- DNM 6700/6700L/6700XL 1300 kg

-

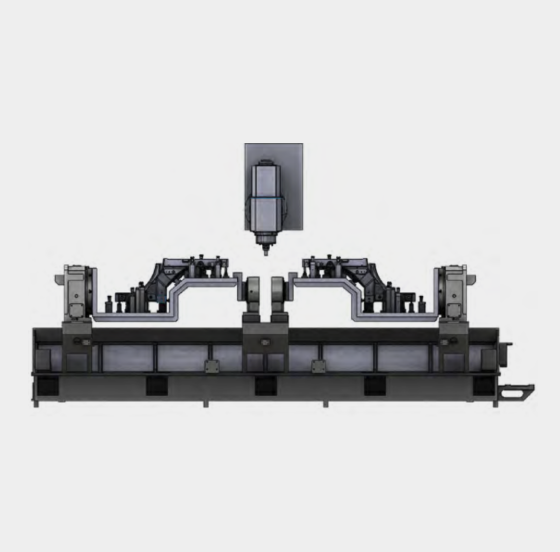

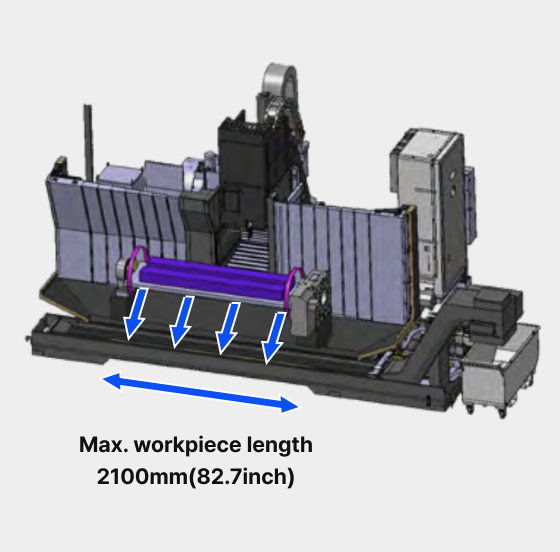

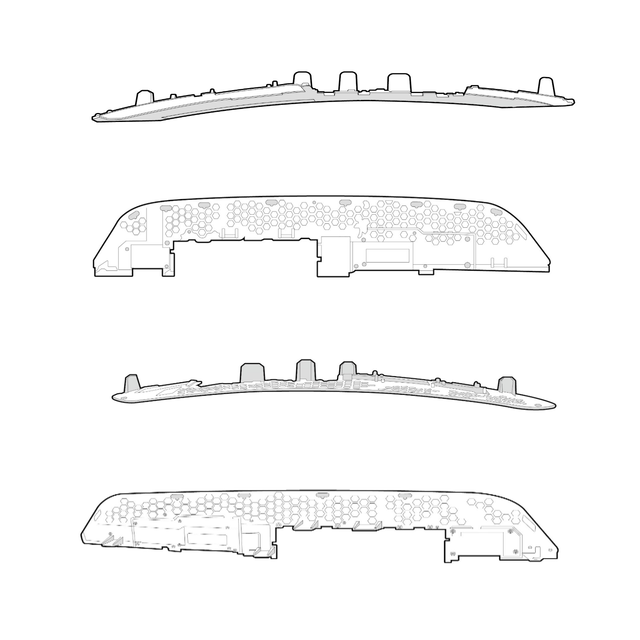

PROFILE_1 Long parts solution Speical bed for easy chip disposal

Speical bed for easy chip disposal- Workpiece to chip conveyor directly

Twin spindle rotary table- High productivity: Set up two workpieces at the same time

machining area

Left/ right A axis

Left/ right A axis- Synchro mode On : Simultaneous

operation of left and right A-axis - Synchro mode Off : Separated

operation of left and right A-axis

Rapid traverse- A-axis 60 r/min

- Travel distance 360 deg

Dual pinion- There is no backlash by applying dual

pinion structure to increase

rigidity

-

PROFILE_2 Optimal Design for the User

Environment Wide machining area

Equipment Layout table Specification T4000 T4000L Width 1600mm 2050mm Length 2560mm 2574mm Height 2324mm 2324mm Distance to table 799mm 799mm - The machine's compact design delivers greater user convenience and requires minimal floor space.

Wide machining area Table size(AxB)

Table size(AxB)- DNM 4500/L 1000{1050} x 450 mm

- DNM 5700/L 1300{1500} x 570 mm

- DNM 6700/L/XL 1500{1600/2200} x 670 mm

Max weight on Table- DNM 4500/4500L 600 kg

- DNM 5700/5700L 1000 kg

- DNM 6700/6700L/6700XL 1300 kg

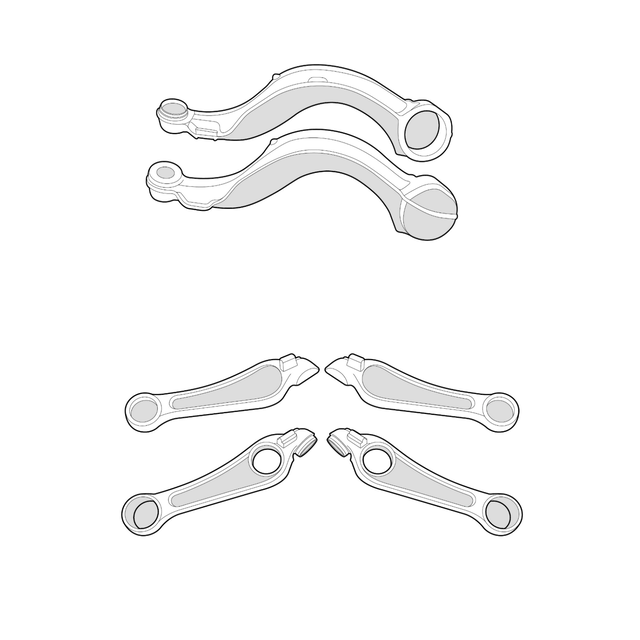

Powertrain / Engines :

A device designed to generate the power needed to move a vehicle (engine), and a device that transmits power to the driving wheels (powertrain)

Engine, clutch, transmission, propeller shaft, gear, axle, etc.

Accessory etc :

Optimal machining solutions for various parts of internal combustion and electric vehicles

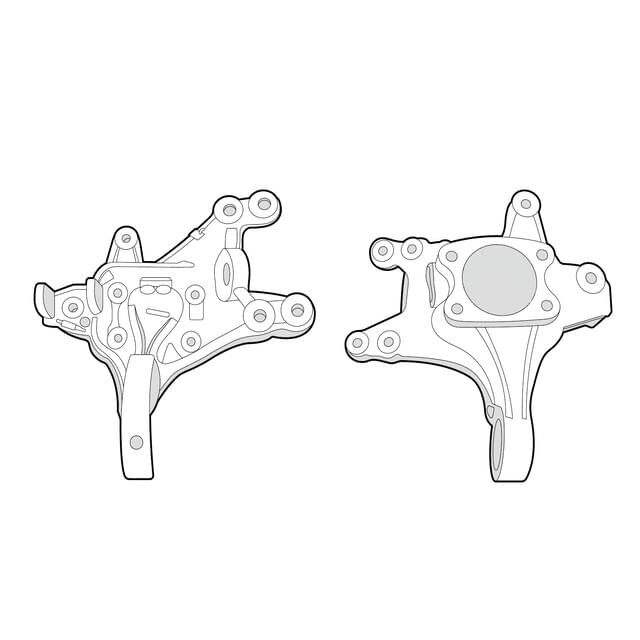

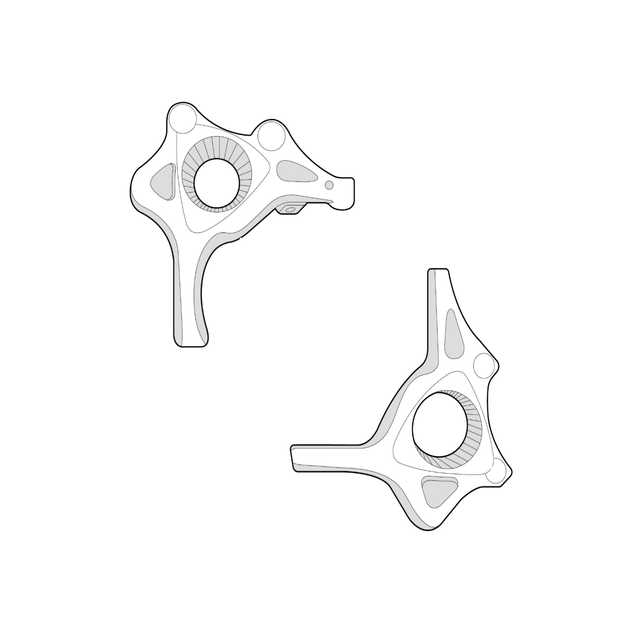

Chassis System Steering :

Optimal machining solutions for various parts of

internal combustion and electric vehicles

Chassis System Suspension :

Optimal machining solutions for various parts of internal combustion and electric vehicles

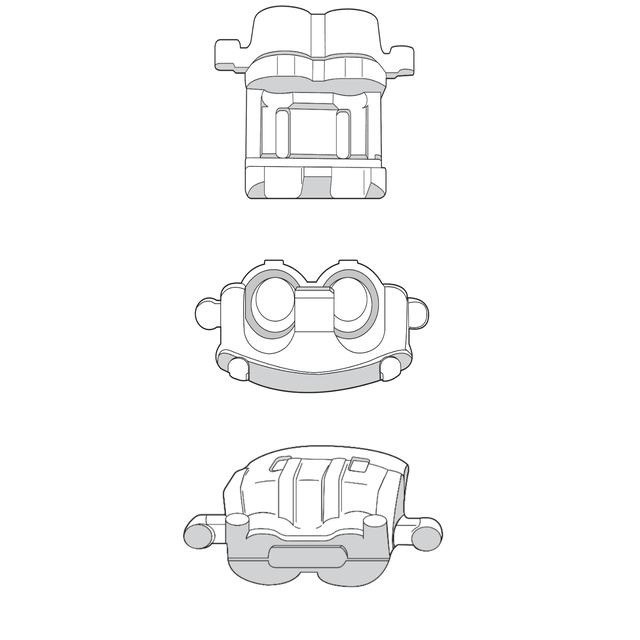

Chassis System Brakes :

A device designed to control and adjust the driving speed or to stop a vehicle’s forward or backward movement.

Brake pedal, Brake booster, Brake drum, Brake disk, Brake line, Master cylinder, Parking brake,etc.

-

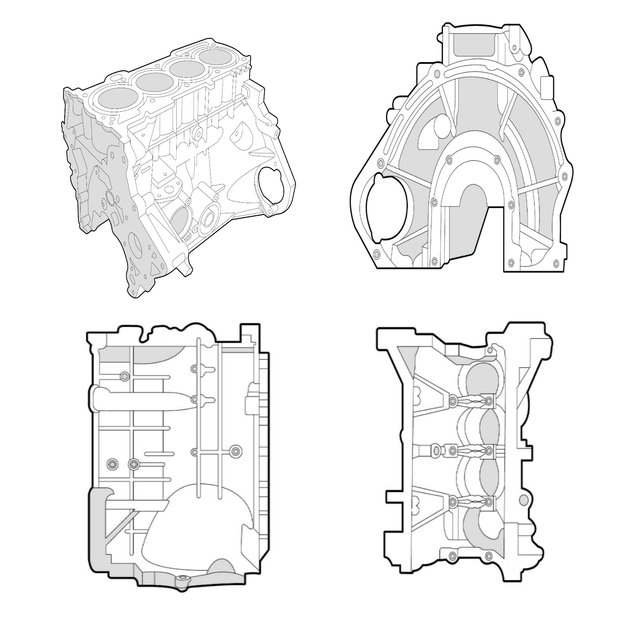

Cylinder Blocks -

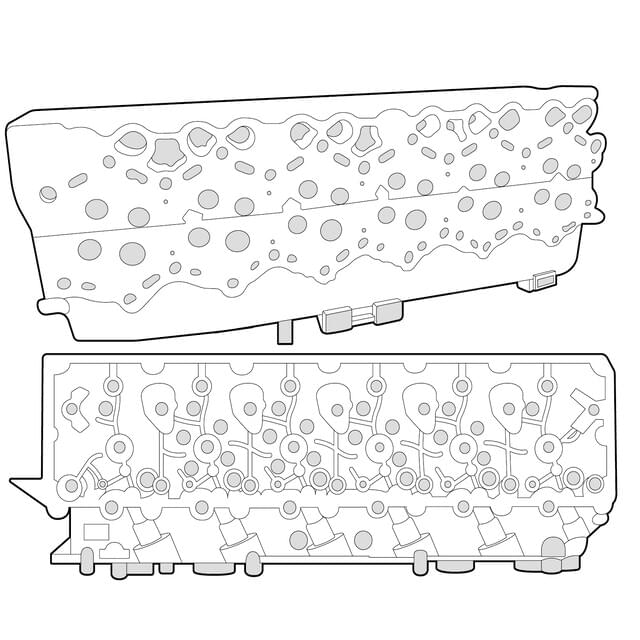

Cylinder Heads -

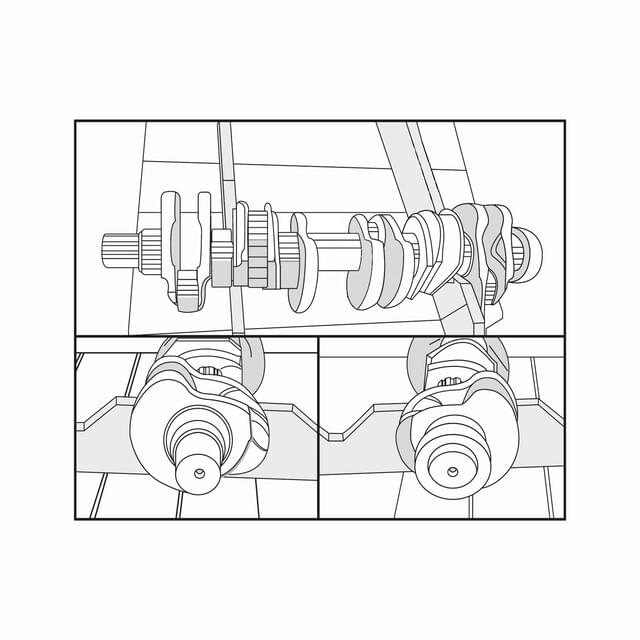

Crankshafts -

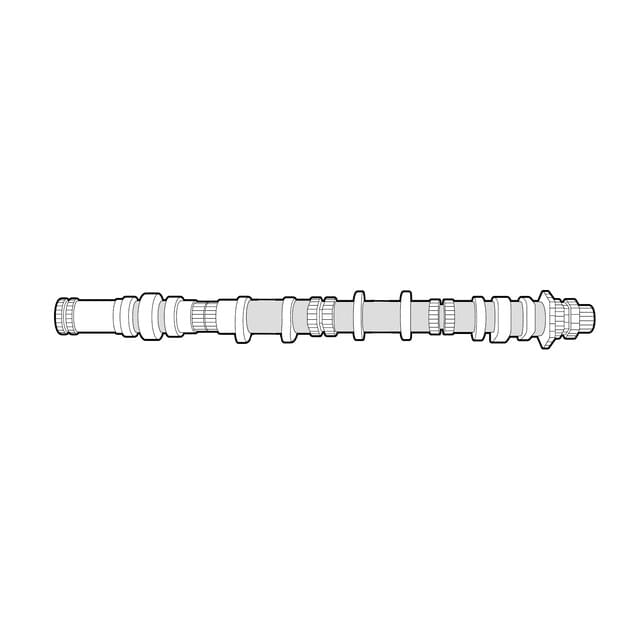

Camshafts -

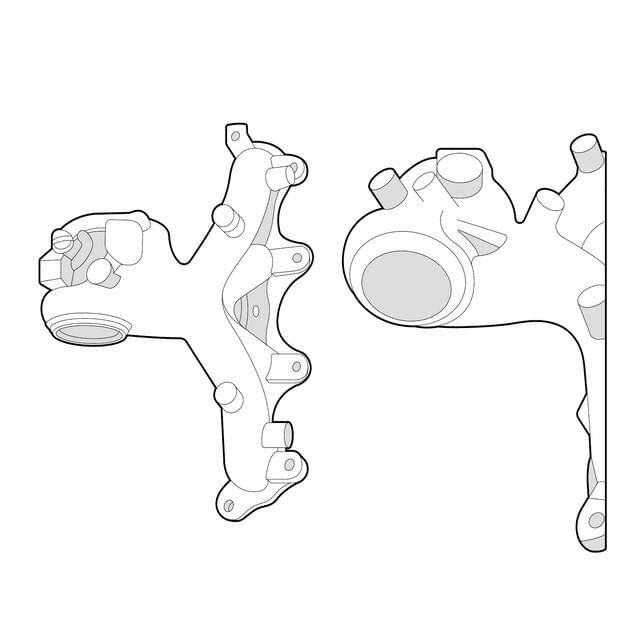

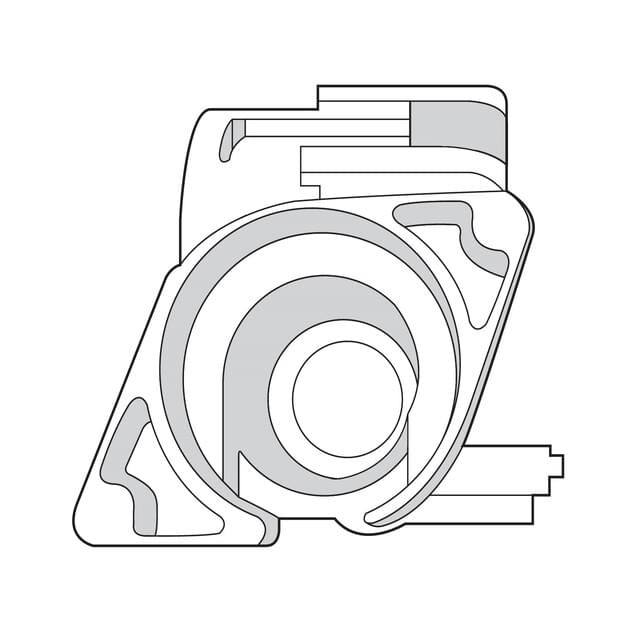

Turbine Housings -

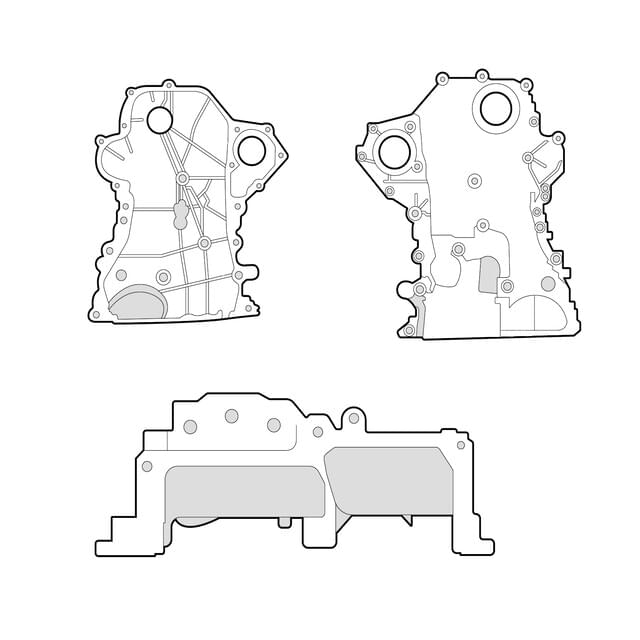

Timing Chain Covers -

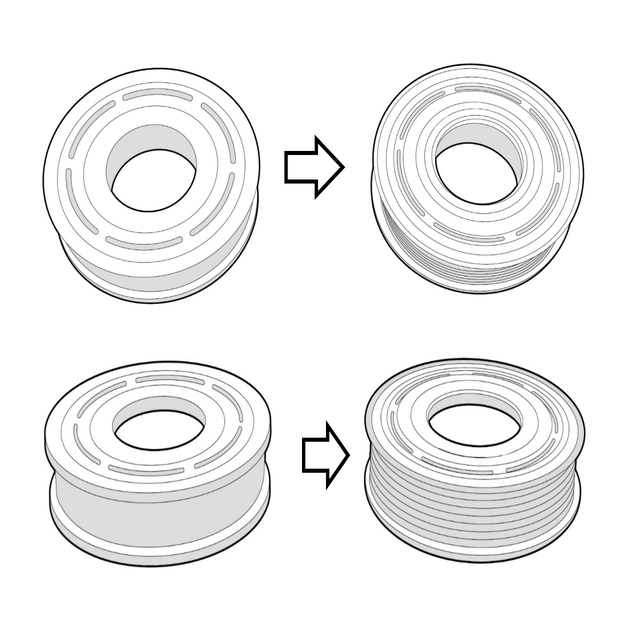

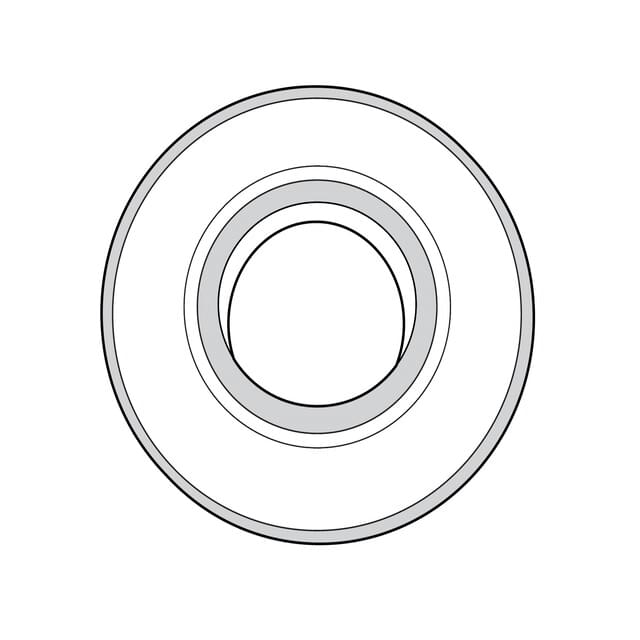

Pulleys -

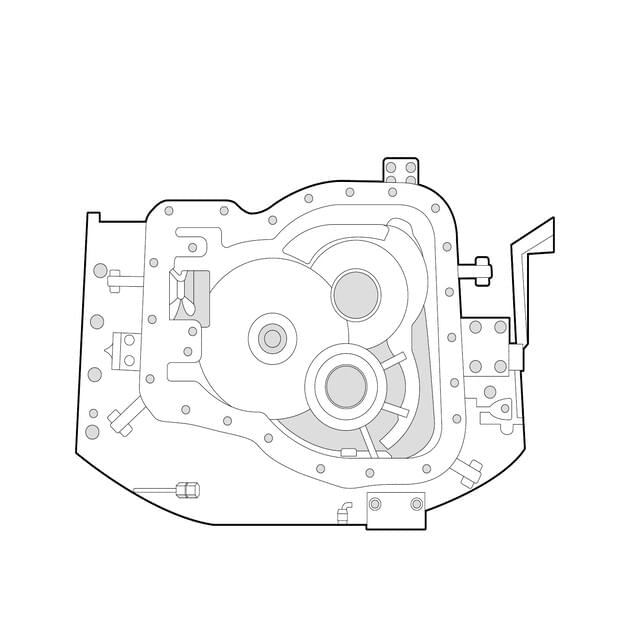

Transmission Cases -

Clutch Hubs -

Axle Housings -

Diffrencial Cases -

Shafts -

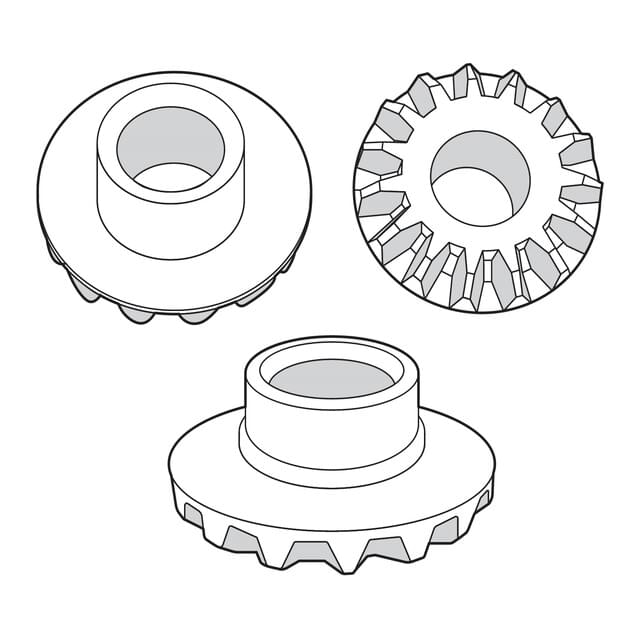

Bevel Gears

-

Aluminum Wheels -

Forged Wheels -

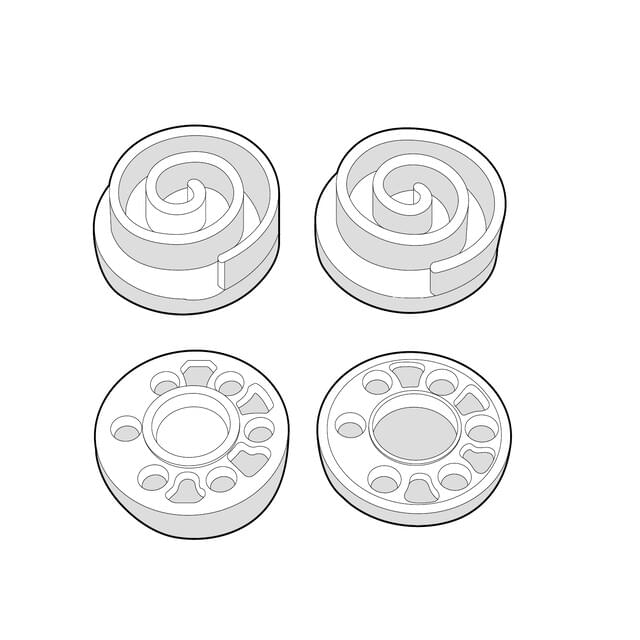

Scrolls -

Compressor Cylinders -

Pulley Clutchs -

Pulleys -

Pump Brackes -

Roters -

Core Plates

-

Rack Housings -

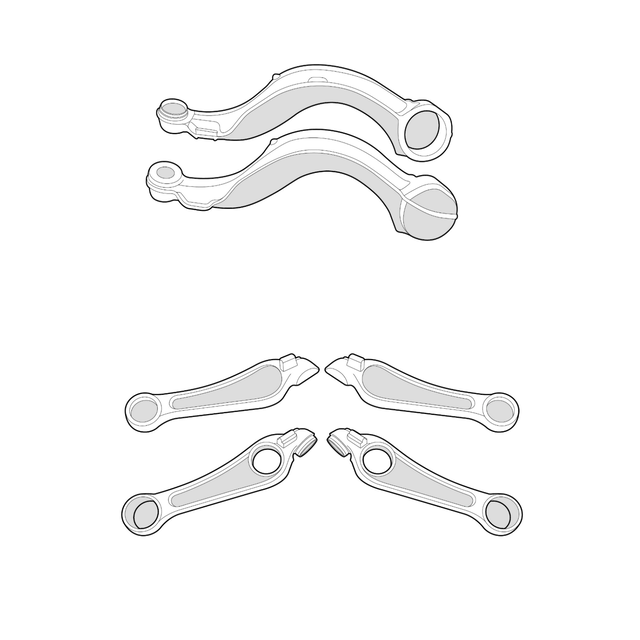

Control Arms -

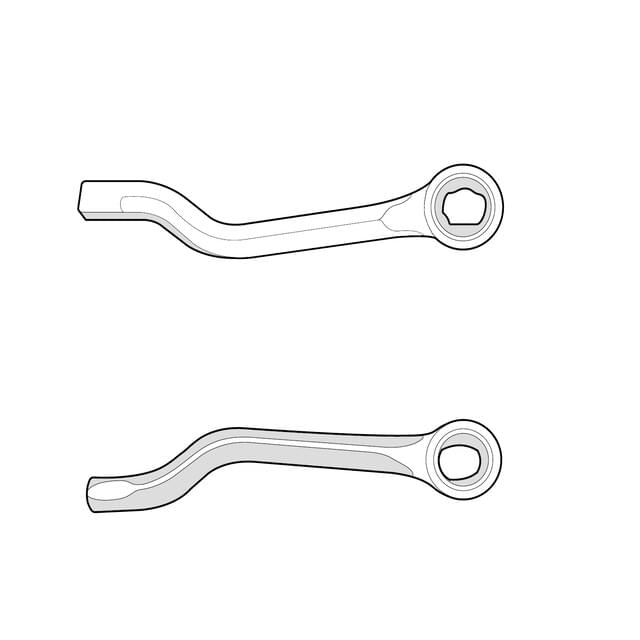

Tie Rods -

Carriers -

Assist Housings -

Outer Rings

-

Rear Carries -

Knuckles -

Control Arms

-

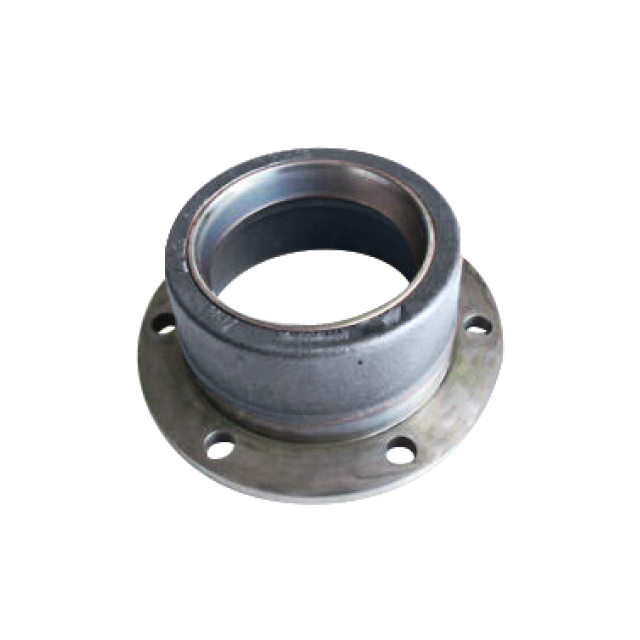

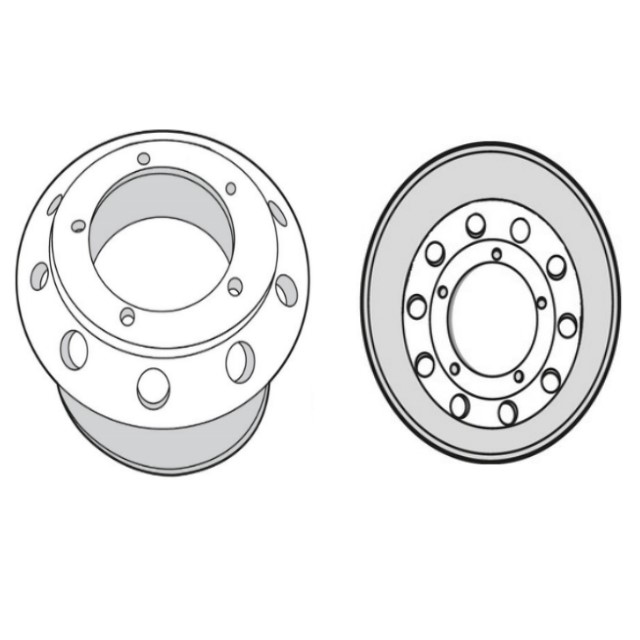

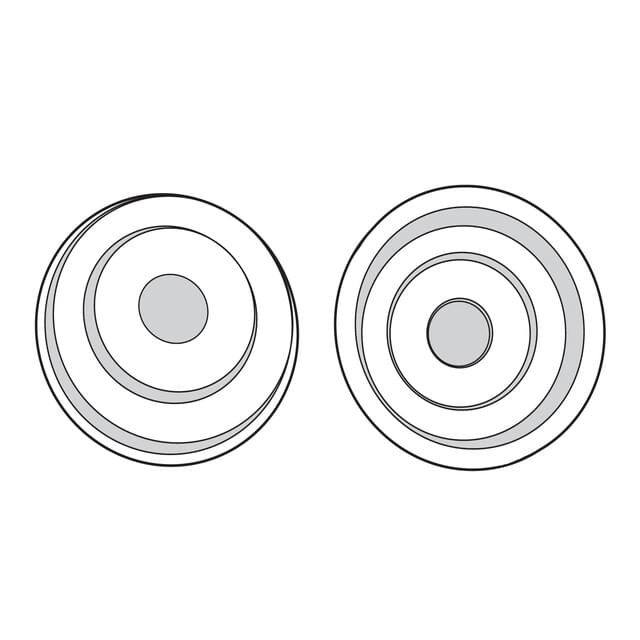

Hub -

_Hub.jpg)

Hub -

Caliper Carriers -

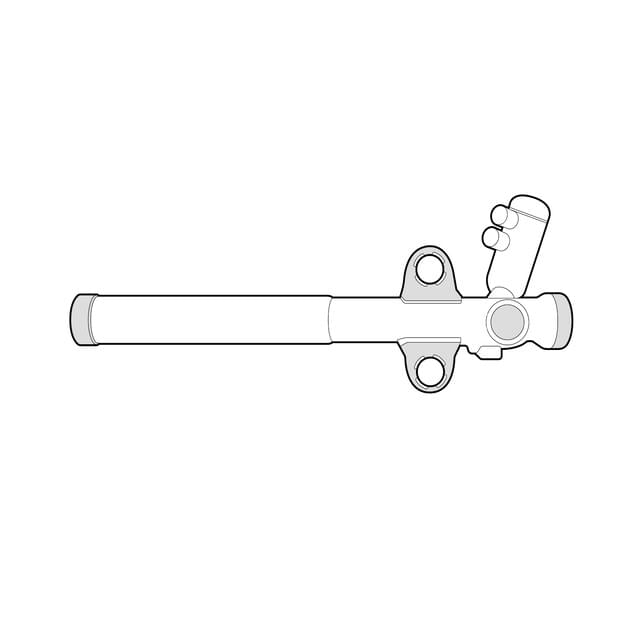

_Master-Cylinder.jpg)

Master Cylinders -

ABS Blocks -

Brake Drums -

Caliper Housing

Our Automotive Industry Customers

DN Solutions provides customers with high-quality solutions that enable them to efficiently manufacture many of the key

components that determine automobile performance, safety, efficiency, and comfort.

- U.S.A

DANA CORPORATION,

EATON CORPORATION,

LINAMAR, TRW - Mexico

VALEO, AAM

- Brazil

Denso, Mahle, WEG

- Germany

AMTEC Auto LTD,

Knorr-Bremse,

Linamar Powertrain - Sweden

Scania Volvo,

Car Corporation - Italy

BREMBO,

DANA ITALIA, SATA - Turkey

AKIS, BMC, OTOKAR

- India

AMTEK AUTO,

RICO AUTO,

BRAKES INDIA,

RAMKRISHNA

FORGINGS - China

Honda Auto,

Jiangling Motors, JAC - Thailand

Delphi Automotive,

Honda Automobile,

Fujikoki - South Korea

GM, MANDO,

HANON System

Our Automotive Industry Customers

DN Solutions provides customers with high-quality solutions that enable them to efficiently manufacture many of the key components that determine automobile performance, safety, efficiency, and comfort.

-

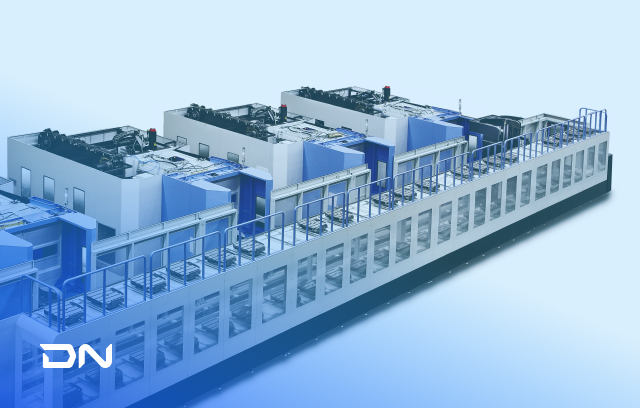

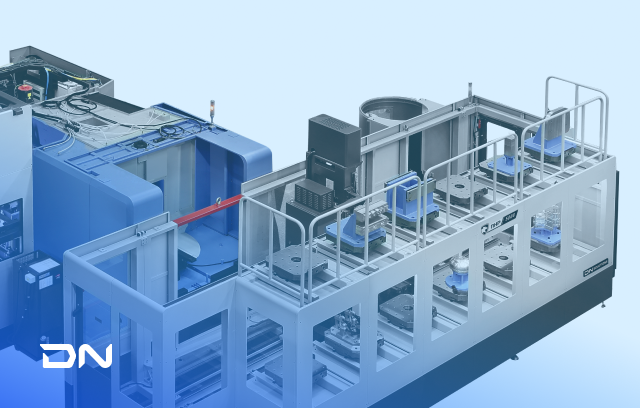

Maximum efficiency with minimum workforce

Maximum efficiency with minimum workforce“DN Solutions’ LPS system, introduced by HYPI, is a linear pallet

system designed to maximize productivity and quality with a

minimum workforce. The 12-pallet LPS is suitable not only for

large factories but also for small and medium-sized firms. Another

great advantage is the perfect service offered by DN Solutions

after the design, establishment and installation of the automated

system. We are currently using the HP 5100 primarily because it

can respond very quickly to frequent changes of workpieces.” -A Company -

Reliable customer service

"We had confidence in DN Solutions' machines due to their stable

operation rate and durability. This is already our fourth project

with DN Solutions. While we were conducting the system line

project, DN Solutions shared its technology with us unreservedly,

and accepted all our requirements including any additional

functions we needed in connection with various regulations.” - B Company